A Systematic Review of Encapsulation and Control Release Technology in food Application

Melaku Tafese Awulachew*

Ethiopian institute of Agricultural research, Addis Ababa, Ethiopia.

*Corresponding Author

Melaku Tafese Awulachew,

Ethiopian institute of Agricultural research, Addis Ababa, Ethiopia.

E-mail: melakutafese12@gmail.com

Received: August 26, 2021; Accepted: December 22, 2021; Published: December 24, 2021

Citation: Melaku Tafese Awulachew. A Systematic Review of Encapsulation and Control Release Technology in food Application. Int J Dairy Process Res. 2021;4(1):71-78.

Copyright: Melaku Tafese Awulachew© 2021. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Abstract

This study is aims to give a brief description ofencapsulation and control release technology in food application with research

reports and verification of well-known common sense in elsewhere, that exist as part of the commonly known and very effective

in food preservation. Besidesthe material give potential information for those who interested for futuredevelopment

perspectives of the sector and also create awareness potentiallyfor readers, traders, Students, factory workers, technologist

and related stakeholder. A process to entrap active agents within a carrier material called Encapsulation and it is a useful

tool to improve delivery of bioactive molecules and living cells into foods. Therefore, encapsulation preserve stability of the

bioactive compounds during processing and storage and to prevent undesirable interactions with food matrix. During encapsulation

process, a large number of substances are used to encapsulate solid or liquid food ingredients. Micro-organisms are

the main agents responsible for food spoilage and food poisoning and therefore food preservation procedures are targeted

towards them. Generally,the selection of encapsulating materials depends on the types, origins, and properties of these food

ingredients.It is being increasingly popular in pharmaceutical, nutraceutical and functional food industries as a highly effective

method that performs various functions; the major being prolonging the shelf-life of the active, masking the undesirable

flavour, colour and taste and controlling the release of bioactive.

2.Introduction

3.Overview Of Encapsulation And Control Release

4.Mechanisms Of Microbial Inactivation

5.Critical Factors Determining Microbial Inactivation

6.Current Emerging Combination Technologies For Food Processing

7.Future Perspective (Development Potentials)

8.Conclusion

9.References

Keywords

Food Preservation; Technology; Encapsulation; Control Release; Future Potential.

Introduction

A process to entrap active agents within a carrier material called

Encapsulation and it is a useful tool to improve delivery of bioactive

molecules and living cells into foods. The encapsulated substance,

except active agent, named as the core, fill, active, internal

or payload phase. The substance that is encapsulating is often

named as the coating, membrane, shell, capsule, carrier material,

external phase, or matrix [1, 2]. In the food industry, encapsulation

process can be applied for a variety of reasons. Encapsulation

is a useful tool to improve delivery of bioactive molecules

(e.g., antioxidants, minerals, vitamins, phytosterols, lutein, fatty

acids, lycopene) and living cells (e.g., probiotics) into foods [1,

3]. In most cases, encapsulation refers to a technology in which

the bioactive components are completely enveloped, covered and

protected by a physical barrier, without any protrusion of the

bioactive components [3]. Produced particles usually have diameters

of a few nm to a few mm [1]. Functional compounds are

used to control flavour, colour, texture or preservation properties.

Bioactive compounds with various potential health benefits are

included, too.

There is a multitude of possible benefits of encapsulated ingredients

in the food industry. Encapsulation aims to preserve stability

of the bioactive compounds during processing and storage and to

prevent undesirable interactions with food matrix. Mainly, bioactive

food compounds are characterized by rapid inactivation. In

addition to the above, encapsulation can be applied for modification

of physical characteristics of the original material in order to

(a) allow easier handling, (b) to help separate the components of

the mixture that would otherwise react with one another, (c) to

provide an adequate concentration and uniform dispersion of an

active agent [4].

These compounds would profit from an encapsulation procedure,

since it slows down the degradation processes (e.g., oxidation or

hydrolysis) or prevents degradation until the product is delivered

at the desired sites [5]. The European Directive (3AQ19a) defines

controlled release as a “modification of the rate or place at which an active substance is released.” Such a modification can be made

using materials with specific barrier properties for manipulating

the release of an active and to provide unique sensory and/or

functional benefits. Addition of small amounts of nutrients to

a food system, for example, may not affect its properties significantly;

however, incorporating high levels of the nutrient either

to meet certain requirements or to treat an ailment will most often

result in unstable and often unpalatable foods. Examples of

such nutrients include fortification with calcium, vitamins, polyunsaturated

fatty acids, and so on, and the associated grittiness,

medicinal and oxidized taste, respectively. Different types of controlled-

release systems have been formulated to overcome these

challenges and to provide a wide range of release requirements.

The two principal modes of controlled release are delayed and

sustained release.

Delayed release is a mechanism whereby the release of an active

substance is delayed from a finite “lag time” up to a point when/

where its release is favored and is no longer hindered. Examples

of this category include encapsulating probiotic bacteria for their

protection from gastric acidity and further release in the lower

intestine, flavor release upon microwave heating of ready-meals

or the release of encapsulated sodium bicarbonate upon baking

of a dough or cake batter.

Sustained release is a mechanism designed to maintain constant

concentration of an active at its target site. Examples of this

release pattern include encapsulating flavors and sweeteners for

chewing gum applications so that their rate of release is reduced

to maintain a desired flavor effect throughout the time of chewing.

A wide range of cores (encapsulants), wall-forming materials

(encapsulating agents), and technologies for controlling the interactions

of ingredients in a given food system and for manufacturing

microcapsules and micro particles of different size, shape, and

morphological properties are commercially viable. Therefore, the

objective of this material is to providebrief overview to the basic

understanding and common process to encapsulate food active

agent and control release system in food processing.

Overview Of Encapsulation And Control Release

Principles and equipment of encapsulation and control release

Wall-Forming Materials: Wall forming materials are a shell material

used for food ingredients encapsulation. Because, a large

number of substances are used to encapsulate liquid or solid food

ingredients; the selection of encapsulating materials depends on

the origin,types, and properties of these food ingredients. Among

various shell materials only some numbers have been certified for

food applications as “overall recognized as safe” materials. In general,

these encapsulating agents are biopolymeric substances such

as lipids, proteins, gums or their derivatives. Materials used in film

coating or matrix formation include several categories:

• Waxes and lipids: Candelilla, beeswax, and carnauba waxes, wax

micro- and wax macroemulsions, modified fats and glycerol distearate,

natural.

• Proteins: soy proteins, gelatins, whey proteins, gluten,zein, and

so on. All these proteins are available both in modified forms and

native.

• Carbohydrates: maltodextrins, starches, chitosan, sucrose, ethyl

cellulose, cellulose acetate, glucose, alginates, chitosan, carrageenan’s,

and so on.

• Food grade polymers: poly vinyl acetate, polypropylene, polybutadiene,

polystyreneand so on.

Carbohydrates: Starch and starch derivatives for instance maltodextrin,

cellulose derivatives for instance carboxymethyl cellulose,

gums for instance gum Arabic, guar gum and chia seed gum and

β-cyclodextrin are the most commonly used carbohydrate-based

wall materials. This is because of their abundant availability, excellent

core protection ability, bland flavour, these wall materials are

used to encapsulate diverse food materials such as oxygen sensitive

and PUFA-rich oil, vitamins, proteins & bioactive peptides,

enzymes and flavour [6-8]. Modified starches are produced by inducing

side chains of lipophilic succinic acid to increase the emulsifying

ability of starch. Moreover, Modified starches are found to

show better protection than native and waxy starch [9] and offer

exciting emulsion stability [10].

Proteins: Superior functional and physicochemical properties

including gel forming ability, emulsifying capacity and film formation

capability make proteinan excellent encapsulating material

which find huge applications in food industries [11, 12]. Gelatin

is the widely used shell matrix used to manufacture highly stable

soft gels of omega-3, vitamin D and fish oil. Milk proteins such

as sodium caseinate and whey protein isolate, and other plant proteins

such as soy proteins, pea proteins have been used as wall

materials for several years. Whey protein has also been reported

as fantastic wall materials for encapsulating sensitive flavours and

PUFA-rich oils. This protein possesses excellent encapsulation efficiency

(up to 89.6%) over other proteins such as soy protein (up

to 75.9%) [13, 14]. The authors found that resultant microcapsules

recovered by spray drying remain stable over 60 days at high

water activity (aw = 0.74 - 0.90) [14]. One of the major limitations

of using protein as encapsulants is their allergenicity to some individuals.

wheat protein (e.g., gluten), Soy proteins, and peanut proteins are

reported to be highly allergenic to a number of individuals. This

not only limits their application but also warrants manufacturer

declaration on the label for their presence in the designed foods.

In addition, proteins are sensitive to structural changes and their

effectiveness as wall materials is greatly dependent such as pH,

ionic strength and temperature of the emulsions or solution [5,

14]. Even Hough, blending these proteins with other materials,

particularly carbohydrate-based biopolymers, such as maltodextrin,

corn syrup solids and lactose has been reported to be an

effective method to minimize environmental effect on their functionality

as encapsulants [15, 16].

Lipids: Since lipids are hydrophobic materials and are insoluble

in water and hence, they are widely used to encapsulate hydrophilic

substances.Many different types of lipids including phospholipids,

glycerides, fatty acidsand waxes have been explored for

their ability to encapsulate food actives [1]. Although lipid-based

encapsulation technology is relatively new and emerging field, it is

becoming highly popular as a means of delivering pharmaceutical,

bioactive food and nutraceutical ingredients. Main types of lipidbased

delivery systems are four: Nano emulsions, nanoliposomes,

solid lipid nanoparticles and nanostructure lipid carriers [17].

Core Materials: Coating substances that are basically film forming

materials can be selected from a wide variety of synthetic

polymers or natural, depending on the characteristics desired in

the final microcapsules the material to be coated. The coating

composition is the main determinant of the functional properties

of the microcapsule and of the method to be used to improve

the performance of a particular ingredient. An effective coating

material should have good rheological properties at high concentration

and ease of manipulation during the process of encapsulation

and also, selected so that it produces a stable emulsion or dispersion

with the active ingredient, and does not react or degrade

the active material during processing and storage. Beside this, it

should meet specified or desired capsule solubility properties and

active material release properties.

Coating materials for encapsulation of food ingredients can be

subdivided into cellulose, gums, lipids, and proteins. Core materials

include flavors, nutraceutical, antimicrobial agents, and

therapeutic actives, vitamins, alkalis, buffers, sweeteners, minerals,

antioxidants, colors, acids, nutrients, enzymes, cross-linking

agents, yeasts, chemical leavening agents, and so on. For instance,

encapsulation by extrusion and spray drying depends primarily

on the carbohydrates used for the encapsulation matrix. Furthermore,

Gums usually used as control crystallization, texturing ingredients,

stabilize emulsions, and inhibit syneresis (the release of

water from fabricated foods), thereby improving coating properties.

Lipids are generally used for encapsulation for water soluble

ingredients. Protein ingredients are also effective in encapsulating

food ingredients. In particular, gelatin is used in coacervation.

Processing technology of encapsulation and control release

Release Triggers: Encapsulation and controlled-release systems

can be designed to respond to one or a combination of triggers

that can activate the release of the entrapped substance and to

meet a desired release target or rate. Triggers can be one or a

combination of the following:

• Temperature: fat/wax matrices

• Moisture: hydrophilic matrices

• pH: enteric coating, emulsion coalescence, and others.

• Enzymes: enteric coating as well as a variety of lipid, starch and

protein matrices.

• Shear: chewing, physical fracture, and grinding

• lower critical solution temperature (LCST) of hydrogels.

The Payload is means to estimate the amount of active (core) entrapped

in a given matrix or wall material (shell) and the percentage

of payload is expressed as Equation: Payload (%) = [core) /

(core + shell)] * 100

Entrapment of Actives in Food Matrices: Encapsulation of

active into an amorphous matrix, generally, involves melting

a crystalline polymer using heat and/or shear to transform the

molecular structure into an amorphous phase. The encapsulant is

then incorporated into the metastable amorphous phase followed

by cooling to solidify the structure and form glass, thus restricting

molecular movements. Carbohydrates are excellent candidates for

encapsulation applications due to the several attributes possessed

by them.

• They form an integral part of many food systems.

• They are cost-effective.

• They occur in a wide range of polymer sizes.

• They have desirable physicochemical properties such as solubility,

melting, phase change and so on.

Sucrose, maltodextrins, native and modified starches, polysaccharides,

and gums have been used in encapsulating flavors, minerals,

vitamins, probiotic bacteria as well as pharmaceutical actives. The

unique helical structure of the amylose molecule, for example,

makes starch a very efficient vehicle for encapsulating molecules

like lipids, flavors, and so on [18]. Some carbohydrates such as

inulin and trehalose can provide additional benefits for encapsulation

applications. Inulin, for example, is a prebiotic ingredient that

can enhance survival of probiotic bacteria while trehalose serves

as a support nutrient for yeasts.

Spray drying and Extrusion are the two main technologies have

been used in large-scale encapsulation applications into amorphous

matrices, though using different mechanisms.

In spray drying, for example, the active is trapped within porous

membranes of hollow spheres, while in extrusion the goal is to

entrap the active in a dense, impermeable glass. Encapsulating actives

via spray drying requires emulsifying the substrate into the

encapsulating agent. This is important for flavor applications, in

particular, considering the fact that most flavors are made up of

components of various chemistries (polarity, hydrophobic to hydrophilic

ratios), thus limiting their stability when dispersed or

suspended in different solvents. Hydrophobicity is one of the

most critical attributes that can play a significant role in determining

flavors’ payload as well as their release in food systems. The

basic principle of spray drying has been adequately covered by

[19].

Briefly, the process comprises atomizing a micronized (1–10-micron

droplet size) emulsion or suspension of an active and an encapsulating

substance and further spraying the same into a chamber.

Drying takes place at relatively high temperatures (210°C inlet

and 90°C outlet), though the emulsion’s exposure to these temperatures

lasts only for few seconds. The process results in free

flowing, low bulk density powders of 10–100-micron size. Optimal

payloads of 20% can be expected for flavors encapsulated in

starch matrices. Maltodextrins and sugars with lower molecular

weight, due to their low viscosities and inadequate emulsifying

activities, result in lower flavor payloads. Several factors can impact

the efficiency of encapsulation via spray drying, mainly those

related to the emulsion (solid content, molecular weight, emulsion

droplet size, and viscosity) and to the process (feed flow rate, inlet/

outlet temperature, gas velocity, and so on).

Release of flavors from spray-dried matrices takes place upon reconstitution

of the dried emulsion in the release medium, water

most often. Reasonable prediction of the release behavior should

take into consideration the complex chemistry of flavors and the

prevailing partition and phase transport mechanisms between

aqueous and non-aqueous phases [20, 21]. Encapsulation into an

amorphous matrix via extrusion has gained wide popularity with

applications ranging from entrapping flavors for their controlled

release to masking the grittiness of minerals and vitamins. Hot

melt extrusion is a highly integrated process with many unique

advantages for encapsulation applications, namely:

• Extruders are multifunctional systems (many unit operations)

that can be manipulated to provide desired processing temperature

and shear rate profiles by varying screw design, barrel heating,

mixing speed, feed rate, moisture content, plasticizers, and

so on.

• Possibility of incorporating actives and other ingredients at different

points of the extrusion process. Heat-labile actives, for

example, can be incorporated via temperature-controlled inlets

toward the end of the barrel and their residence time in the extruder

can be minimized to avoid degradation of the active and to

preserve its integrity.

• Extruders are also formers: encapsulated products can be recovered

in practically any a desired shape or size (pellets, rods, ropes,

and so on).

• Only very limited amount of water is needed to transform carbohydrates

from their native crystalline structure to amorphous

glassy matrices in an extruder, thus limiting the need for expensive

downstream drying.

• High payload: up to 30% can be expected when encapsulating

solid actives in extruded pellets.

• Economics: attributes such as high throughput, continuous

mode, and limited need for drying make extrusion a very attractive

process for manufacturing encapsulated ingredients.

Carbohydrate (encapsulating matrix), a mixture of sucrose and

maltodextrin, is dry fed and melted by a combination of heat

and shear in the extruder barrel so that the crystalline structure

is transformed into an amorphous phase. It should be cautioned

that although glass transition and associated microcapsule stability

are clearly related to the material properties of the matrix and

rates of crystallization, there is growing evidence that in the glass

transition region small molecules are more mobile than might be

expected from the high viscosity of the matrix [22].

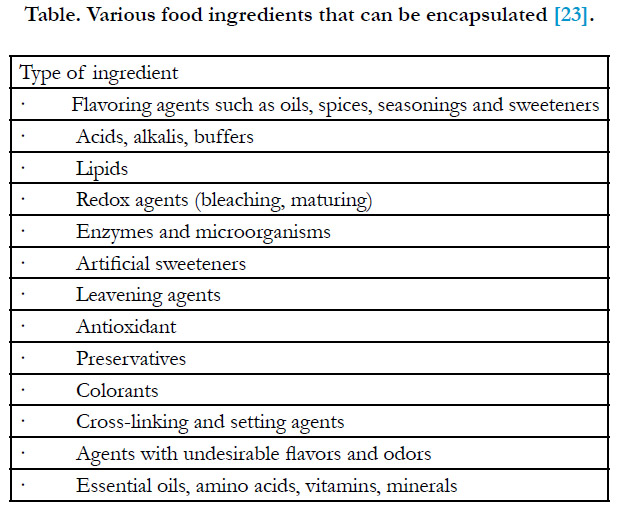

Types of Encapsulated Food Ingredients

The types of food ingredients that can be encapsulated are shown

in Table [23]. Applications for encapsulation have been slow to

expand since the technique was formerly thought to be too expensive

and highly specific. However, since production volumes

have increased and become more cost-effective, a wide variety of

encapsulated foods can be found. Flavored oil encapsulated in

food-grade hydrocolloid is an example of water-soluble capsules

commonly found.

Flavoring agents and spices are encapsulated by a variety of processes

and offer numerous advantages to the food processor. Citrus

oil and other flavors, for example, provide enhanced stability

to oxidation, volatilization, and light, controlled release, resistance

to clumping and caking, and substantially longer shelf life [24].

Encapsulated flavors are available as natural flavors, natural and

artificial flavors, essential oils (menthol, peppermint, and spearmint),

oleoresins, natural flavors with other natural flavors added,

chips, and artificial flavors. Although encapsulated flavors may

be used in many different applications, they are currently gaining

considerable attention for their stability through high-temperature/

short-time processes such as those utilized in preparing extruded

foods and microwavable foods.

Acidulants are added to foods as flavor modifiers, preservatives,

and processing aids. Unencapsulated food acids can react with

food ingredients to produce many undesirable effects. These include

deceased shelf life of citrus flavored foods and starch containing

foods, loss of flavor, degradation of color, and separation

of ingredients. Encapsulated food acids resolve these and other

problems because they preclude oxidation and provide controlled

release, with their coating formulated to dissolve or melt at specific

temperatures. Furthermore, encapsulated acids reduce hygroscopicity,

reduce dusting, and provide a high degree of flowability

without clumping. Examples of encapsulated acidulants that are

commercially available are adipic acid, ascorbic acid, citric acid,

fumaric acid, lactic acid, and malic acid [24]. Encapsulated acidulants

can be used as dough conditioners and in meat processing

(e.g., in cured meat products). For example, uncoated lactic acid

and citric acid cannot be used in the production of cured meats

because they react almost instantaneously with the meat, rendering

it unsuitable for further processing. However, an encapsulated

acid that is formulated for delayed release at smoldering temperatures

can be used, reproducing the same pH as that obtained

with lactic acid bacteria, eliminating the need for fermentation.

Thereby, production time can be reduced.

Microencapsulation also enables ingredients such as enzymes to

maintain their viability for extended periods of time, avoiding their

exposure to ions, protons, free radicals or other type of deleterious

agent. Sweeteners are often subject to the effects of moisture

and/or temperature. Encapsulation of sweeteners, namely sugars

and other nutritive sweeteners, reduces their hygroscopicity, improves

their flowability, and prolongs their sweetness perception.

Sodium chloride, encapsulated with a variety of coatings, including

partially hydrogenated vegetable oil, is used in formulations to

control color degradation, rancidity, water absorption, and yeast

growth. The encapsulated form also improves flowability and reduces

clumping and caking. Typical product applications include

ground meats, pretzel snacks, and yeast dough [24]. Leavening

agents such as sodium bicarbonate are used in baked goods to

achieve volume andlightness of texture. Encapsulated sodium bicarbonate

protects the base from premature reaction with acid or

water, and delays the release of its contents until optimum baking

conditions are present. This ensures that maximum leavening is

achieved and proves to be economically attractive.

Micro-organisms are the main agents responsible for food spoilage

and food poisoning and therefore food preservation procedures

are targeted towards them. Food preservation methods

currently used by the industry rely either on the inhibition of

microbial growth or on microbial inactivation. Methods which

prevent or slow down microbial growth cannot completely assure

food safety, as their efficacy depends on the environmental conditions.

Microbial can be inactivated through the treatment by heat,

chemical agents, radiations and the combination of these.

Inactivation by Heat

Heat has been widely used in the food industry as a preservation

agent, since it is capable of inactivating most microorganisms

and enzymes present in foods. Therefore, heat is a method that

can simultaneously guarantee food safety and food stability. Heat

treatments can be classified into two groups depending on their

intensity and their objective: pasteurization and sterilization treatments.

Pasteurization treatments aim to inactivate vegetative cells

of pathogenic species present in foods; they also extend shelf

life, as long as foods are maintained under refrigeration conditions.

Sterilization treatments are applied in order to guarantee

the stability of the food product at room temperature, an objective

that requires the application of temperatures above 100°C in

most cases. Such intense treatments are capable of inactivating

microbial spores as well as many enzymes and toxins present in

foods, but can also severely modify their organoleptic and nutritional

properties. Thermal treatments are widely used because of

their capacity to inactivate vegetative cells, bacterial spores, yeast

and molds. The type of inactivated microorganism depends, of

course, on the treatment’s intensity. The degree of heat resistance

of different microbial groups varies widely, due to their differing

structure and composition, as well as the mechanisms of resistance

they are able to develop. The application of this basic knowledge

could help improve the design of current pasteurization processes,

leading to milder and/or more effective treatments that

could fulfill consumer requirements for fresh-like foods while

maintaining the advantages of traditional heat treatments [25].

Inactivation by irradiation

Irradiation of foods and feeds for the purpose of killing indigenous

microbes, and thereby extending shelf life, has been recognized

as a preservation technique for several decades. Irradiation

also can be successfully applied to fresh fruits and vegetables for

the purpose of controlling disease and deterioration caused by

molds as well as for achieving insect disinfestation.

The survival of microbial cells upon treatment with irradiation

depends on several factors [26]. These include the nature and extent

of direct damage produced inside the vital target, the number,

nature, and longevity of irradiation-induced reactive chemical

species, and the inherent. ability of the cell to withstand these

assaults and undergo repair. Resistance also depends on extracellular

environmental conditions such as pH, temperature, and

chemical composition of the food in which cells are suspended.

Ionizing irradiation damages DNA at the cellular level, thus debilitating

normal biochemical processes.

Chemical inactivation

There are many chemicals that will kill or inhibit the growth of

microorganisms. An antibiotic generally refers to a chemical that

can be used on or inside a patient (humans, pets, livestock, etc.)

to inhibit the growth of microbes or kill microbes. Commonly

used chemical preservatives include sorbic acid, benzoic acid, and

propionic acid, and their more soluble salts potassium sorbate,

sodium benzoate, and calcium propionate, all of which are used

to control the growth of molds in acidic foods.

Microbial inactivation by irradiation, ultrasound under pressure,

HHP and PEF has been found to depend on many factors. Effective

comparison of data published in literature is hampered by the

diversity of equipment’s and experimental conditions employed

by the different authors. Nevertheless, this section tries to give an

overview on the most relevant factors affecting resistance to novel

technologies. The factors are classified into three groups: process

parameters, microbial characteristics and product parameters.

Process parameters

Some process parameters are intrinsic to each technology and no

general conclusions can be drawn. For instance, the intensity of

an irradiation treatment is given by the irradiation dose absorbed,

as the radiation energy is normally fixed [25]. Critical inherent

parameters for ultrasound under pressure are treatment time, amplitude

of the ultrasonic waves and external pressure applied [26].

Microbial characteristic

Maximum inactivation levels attained with each technology will

depend on factors such as equipment technical developments and

food characteristics. The point is that comparison of data is compered

by the different equipment’s, treatment media, strains, etc.

Microbial resistance to different physical agents depends not only

on the intrinsic resistance of the micro-organisms but also on

their physiological state. It is well known that bacterial heat resistance varies widely depending on the growth phase, growth temperature

and exposure to previous stressing environments [27].

Product parameters

Environmental factors, such as composition of the treatment medium,

pH, water activity or addition of preservative substances,

strongly affect the resistance of micro-organisms to heat. The

relative influence of such factors on microbial resistance to novel

technologies depends on their mechanisms of action. One of

the most important factors influencing irradiation sensitivity is

the composition of the treatment atmosphere. The presence of

oxygen during irradiation has been found to enhance lethal effect

because of oxygen radical formation [25].

Microwave Combination Technology

food products heated by MW shows better retention in color, texture,

and flavor compared with conventionally treated products,

MW heating is associated with numerous problems, such as nonuniform

heating, partial overheating, and limited penetration [28,

29]. Conventional methods such as vacuum drying (VC) and hot

air (HA) heating can preserve the quality of perishable agricultural

products without any damage during processing; however,

it takes considerable time and consumes more energy with low

energy efficiency to complete the processing [30]. MW technology

combined with the aforementioned conventional methods

has been investigated particularly in drying and baking processes.

Infrared Radiation Combination Technology

IR heating is considered a promising method especially for drying

processes, observed problems in IR drying include scorching

heat on the surface of food products and a limited IR penetration

depth [31]. Case hardening is a troublesome problem occurring

in conventional HA drying process because the surface

of food material is dried first, and as drying process progress,

the dried surface of food becomes a barrier to heat transfer [32].

To prevent undesirable phenomenon caused by either IR or conventional

heating methods, a number of studies on dehydration

of food products using integrated IR and conventional methods

have been conducted.IR-assisted HA drying processes for fruit

and vegetable has been evaluated and developed [33, 34].

High-Pressure Processing Combination Technology

High-pressure processing (HPP) has been mainly applied to pasteurize

liquid food products; however, it often times could not

inactivate bacterial spores (e.g., Bacillus and Salmonella) which are

heat and acidic resistant [35]. Therefore, thermal treatment has

been applied to HPP as a pretreatment step. The effectiveness

of HPP combined with thermal treatment (TH) on the inactivation

of PMEs and the inactivation kinetics in various agricultural

products were evaluated by a number of researchers [36].

Radio Frequency Electric Field Combination Technology:

Ukuku and Geveke [37] developed a combined UV light and RF

electric field (RFEF) system to inactivate Escherichia coli K-12

in apple juice. Apple juice was preheated up to 25, 30, and 40 0C

and then treated by individual UV, RF and combined UV with

RF treatment. After all treatments, apple juice samples inoculated

with microbial contaminant were analyzed for leakage of UVabsorbing

substances as the function of cell membrane injury.

The individual UV and RFEF treatment at 400C showed the minimum

surviving population of E. coli K-12 in the juice. A higher

bacterial inactivation was expected when the two treatments were

combined; however, the determined number was only an approximately

0.6 log microbial reduction higher than UV treatment

alone. Although inactivation of E. coli K-12 in apple juice was not

influenced by the combination system, UV-absorbing substances

determined in the juice treated by combined treatment was substantially

different from individual UV treated sample. The results

suggested that combination treatment would damage bacterial

cells and lead to more leakage of intracellular UV-absorbing substances

than individual treatment.

Combined RF with HA treatment was investigated to improve

the quality and mold control of enriched white bread [38]. Prior

to RF–HA treatment, the bread columns inoculated with mold

spores were kept under a sterile hood in order to equilibrate moisture

content in the breads. Additionally, target HA and treatment

temperatures controlled by an electrical fan heater and RF power

were evaluated to maximize the mold lethal condition. Visible

mold growth was observed from the surface of untreated bread

loaves stored for five weeks at room temperature; on the other

hand, mold was found in the sample after an extra four weeks

using the combined RF–HA treatment. Moisture migration from

the bread crumb to crust was caused by generation of internal

vapor pressure during the RF heating. The consequent moisture

loss in the bread crumb and increased moisture at the crust led to

a more even distribution of moisture in the treated bread samples.

Combined RF and HA treatment had little effect on the water

activity of breads during storage.

Pulsed Electric Field combination technology: Synergistic effect

of combined thermal treatment (TH) and pulsed electric field

(PEF) on inactivation of microorganisms in liquid food products

has been investigated by a number of researchers [39, 40]. In

these studies, liquid food products (such as salad dressing, liquid

whole egg, liquid egg york, apple juice, fruit smoothie-type beverage)

pretreated using a heat exchanger, heating coil, or hot water

bath at different temperatures were sequentially applied to the

pulsed electric field (PEF) treatment. The effect of sequential TH

and PEF treatment on inactivation of microbial contaminants,

i.e., Lactobacillus plantarum, Escherichia coli O157:H7, Salmonella

enteritidis in respective salad dressing, liquid whole egg, and

liquid egg yolk was also investigated [39, 40]. Prior to PEF treatment,

the liquid food product was preheated up to a certain temperature

in the hot water bath. Preheated sample flowed between

two disk electrodes and then through an electric field with a range

of 9–15 kV/m with different pulse numbers and high frequency.

The pulse width and frequency were adjusted using external transistor–

transistor logic (TTL) with a frequency trigger. Increasing

the pretreatment temperature of liquid food product (apple juice

and liquid egg yolk) and higher electric field strength had a significant

effect on the inactivation of peroxidase (POD), polyphenol

oxidase (PPO), and E. coli O157, as well as, lower D-values [39].

Ohmic Heating Combination Technology: Combined ohmic

and plate heating system for cooking hamburger patties was developed for the enhancement of physical properties of the patties

[41]. A domestic plate grill was modified for the combination

system. The plate was preheated first and then 50 V of alternating

current was applied for OH. The required cooking time was determined

to be 117 and 163 s for the combined and conventional

techniques, respectively. The elasticity index of the conventionally

cooked meat has a slightly higher value than that of cooked meat

by ohmic–plate heating. This suggested that the meat cooked by

the combination system would be less chewy. Otherwise, the mechanical

properties of the meats cooked by individual plate and

OH methods were very similar. The application of OH for cooking

of hamburger patties did not affect the taste and texture of

the meat.

Encapsulation technology has been used in various industries for

more than seven decades, there have been several advancements

in both the science as well as the practical application of this technique

since its first commercial application in 1950. It is being increasingly

popular in pharmaceutical, nutraceutical and functional

food industries as a highly effective method that performs various

functions; the major being prolonging the shelf-life of the active,

masking the undesirable flavour, colour and taste and controlling

the release of bioactive. Encapsulation methods for new bio-actives

are being explored and research advancement is underway to

improve the process and product characteristics.

Innovative food-grade encapsulants are being explored to reduce

the production costs and meet other technical specifications and

consumer expectations. With the escalating demand of functional

foods including omega-3s, probiotics, vitamins and phytochemicals,

these functional ingredients are being incorporated into

wide range of products such as breads, milk, fruit juices, tortillas,

chocolate, yoghurt drinks, spreads, peanut butter, eggs and meat.

Accordingly, various methods of microencapsulation of different

bioactives have been developed. At present, spray drying-based

microencapsulation method is being widely used in various industrial

applications; however, more advanced methods including

complex coacervation are gaining increased attention in recent

years. Complex coacervation technology has been reported to

receive a high product yield and the resultant product possesses

prolonged stability even at a very high payload (up to 99%). In addition,

it yields products with lowest unit product cost [43]. The

biggest disadvantage of this technology is limited availability of

shell materials. So far, gelatin is the only protein which is successfully

used in commercial scale.

A number of studied have reported that the plant proteins are capable

of forming coacervates in the presence of polysaccharides

[44, 45]. This corroborates that plant proteins can be used instead

of animal proteins in complex coacervation process. Reference

[46] used α-gliadin (cereals) and pea globulin (legume) in complex

coacervation process. These authors found that both these proteins

form excellent complex coacervates with the gum Arabic.

However, the application of α-gliadin in the coacervation process

will not achieve widespread acceptance as this protein is associated

with some kind of allergenicity in some individuals [46]. So,

there is a need to test other plant polysaccharides for their potential

as encapsulating and delivery vehicles of active ingredients.

There are certain characteristics which are looked for before using

a biopolymer as an encapsulant. Among them are emulsifying

and interfacial properties, film forming abilities, solubility and gelforming

properties. Emulsifying properties of flaxseed protein,

chia seed protein and lentil protein have been evaluated in recent

years [44, 47, 48]. It was found that emulsions stabilized by flax

protein concentrate (FPC) at neutral pH and in the absence of

salt had a smaller droplet size and higher surface charge which

makes them good candidates to be used in coacervation process.

FPC-stabilized emulsions were more stable against the effect of

salt concentration.

The FPC can be effective stabilizing emulsions where droplet size

and zeta-potential are major factors influencing the emulsion stability.

Flaxseed gum is also found to possess good potential in

stabilizing the protein-based emulsions. Encapsulating unstable

and bioactive core materials with a protein-gum complex shell

matrix isolated from the same plant source is a very recent idea

of microencapsulation. Reference [47] successfully encapsulated

flaxseed oil (core) by novel matrix of flaxseed protein-flaxseed

gum complex coacervate. Similarly, [44] successfully encapsulated

chia seed oil using chia seed protein-gum complex coacervate

shell matrix. The authors have compared the effectiveness of protein

only and gum only shell matrix with the complex coacervate

shell matrix and concluded that complex coacervation based shell

matrix is more effective over the other two. However, this laboratory

experiments need further study for their effectiveness and

reproducibility in pilot plant or commercial trials.

Conclusion

There are various reasons of encapsulation, many bioactive ingredients

are encapsulated to enhance their longevity and functionality.

Several bioactive ingredients are encapsulated to prevent

their degradation from environmental stressors and control their

release in the gastrointestinal tract. For example, baking yeast and

dough conditioners are encapsulated to increase their performance

or to overcome other processing challenges. It has been

reported that uncoated chemical leaveners release carbon dioxide

prematurely. This is even more prominent in warmer environments.

In addition, ingredient degradation or flavour loss during

the baking process can occur in systems where uncoated ingredients

are used. For instance, PUFAs-rich oils are encapsulated to

prevent or minimize their oxidation. Bioactive peptides are encapsulated

to control their release in targeted site. Therefore, encapsulation

method is dependent on the nature of core material

and intended use of the final product. As a consequence, various

methods of encapsulation are developed.

References

-

[1]. Zuidam NJ, Nedovic V. Encapsulation technologies for active food ingredients

and food processing. 2010.

[2]. Fang Z, Bhandari B. Encapsulation of polyphenols–a review. Trends in Food Science & Technology. 2010 Oct 1; 21(10): 510-23.

[3]. de Vos P, Faas MM, Spasojevic M, Sikkema J. Encapsulation for preservation of functionality and targeted delivery of bioactive food components. International dairy journal. 2010 Apr 1; 20(4): 292-302.

[4]. Desai KG, Jin Park H. Recent developments in microencapsulation of food ingredients.Drying technology. 2005 Jul 1; 23(7): 1361-94.

[5]. Lesmes U, McClements DJ. Structure–function relationships to guide rational design and fabrication of particulate food delivery systems.Trends in Food Science & Technology. 2009 Oct 1;20(10):448-57.

[6]. King W, Perry P. Modified starch encapsulating agents offer superior emulsification, film forming, and low surface oil [Incorporation into dry food systems].Food Product Development. 1976.

[7]. Drusch S, Serfert Y, Schwarz K. Microencapsulation of fish oil with n‐octenylsuccinate‐ derivatised starch: Flow properties and oxidative stability. European Journal of Lipid Science and Technology. 2006 Jun;108(6):501-12.

[8]. Jeon YJ, Vasanthan T, Temelli F, Song BK. The suitability of barley and corn starches in their native and chemically modified forms for volatile meat flavor encapsulation. Food Research International. 2003 Jan 1;36(4):349-55.

[9]. Trubiano PC,Lacourse NL. Emulsion-Stabilising Starches: Use in Flavor. In: Risch SJ and Reineccius, GA., Eds., Flavor Encapsulation, American Chemical Society, Washington. 1988. 45-54.

[10]. Bylaitë E, Venskutonis PR, Maþdþierienë R. Properties of caraway (Carumcarvi L.) essential oil encapsulated into milk protein-based matrices. European Food Research and Technology. 2001 Jun;212(6):661-70.

[11]. Li JK, Wang N, Wu XS. Gelatin nanoencapsulation of protein/peptide drugs using an emulsifier-free emulsion method.J Microencapsul. 1998 Mar- Apr;15(2):163-72. PMID: 9532522.

[12]. Kim YD, Morr CV, Schenz TW. Microencapsulation properties of gum arabic and several food proteins: liquid orange oil emulsion particles. Journal of Agricultural and Food Chemistry. 1996 May 16; 44(5): 1308-13.

[13]. Jimenez M, Garcia HS, Beristain CI. Spray-drying microencapsulation and oxidative stability of conjugated linoleic acid.European Food Research and Technology. 2004 Nov;219(6):588-92.

[14]. Damodaran S. Protein stabilization of emulsions and foams. Journal of Food Science. 2005 Apr;70(3):R54-66.

[15]. Sheu TY, Rosenberg M. Microstructure of microcapsules consisting of whey proteins and carbohydrates. Journal of Food Science. 1998 May;63(3):491- 4.

[16]. Keogh MK, O'kennedy BT, Kelly J, Auty MA, Kelly PM, Fureby A, et al. Stability to oxidation of spray‐dried fish oil powder microencapsulated using milk ingredients. Journal of Food Science. 2001 Mar;66(2):217-24.

[17]. Fathi M, Mozafari MR, Mohebbi M. Nanoencapsulation of food ingredients using lipid based delivery systems. Trends in food science & technology. 2012 Jan 1;23(1):13-27.

[18]. Conde-Petit B, Escher F, Nuessli J. Structural features of starch-flavor complexation in food model systems. Trends in food science & technology. 2006 May 1; 17(5): 227-35.

[19]. Masters K. Spray drying handbook. Spray drying handbook. 1985. [20]. Labrousse S, Roos Y, Karel M. Collapse and crystallization in amorphous matrices with encapsulated compounds. Sciences des aliments. 1992;12(4):757-69.

[21]. Shimada Y, Roos Y, Karel M. Oxidation of methyl linoleate encapsulated in amorphous lactose-based food model. J Agric Food Chem. 1991 Apr;39(4):637-41.

[22]. Parker R, Ring SG. Diffusion in maltose-water mixtures at temperatures close to the glass transition.CarbohydrRes. 1995 Aug 25;273(2):147-55. [23]. F. Gibbs, SelimKermasha, InteazAlli, Catherine N. Mulligan B. Encapsulation in the food industry: a review. Int J Food SciNutr. 1999 Jan 1;50(3):213-24.

[24]. Shahidi F, Han XQ. Encapsulation of food ingredients.Crit Rev Food Sci- Human Nutr. 1993 Jan 1;33(6):501-47.

[25]. Gould GW. Heat-induced injury and inactivation.Mechanisms of action of food preservation procedures. 1989:11-42.

[26]. Farkas J. Microbiological safety of irradiated foods. Int J Food Microbiol. 1989 Aug 1;9(1):1-5.

[27]. Gentry TS, Roberts JS. Design and evaluation of a continuous flow microwave pasteurization system for apple cider. LWT-Food Science and Technology. 2005 May 1;38(3):227-38.

[28]. Nguyen LT, Choi W, Lee SH, Jun S. Exploring the heating patterns of multiphase foods in a continuous flow, simultaneous microwave and ohmic combination heater. J Food Eng. 2013 May 1;116(1):65-71.

[29]. Varith J, Noochuay C, Netsawang P, Hirunstitporn B, Janin S, Krairiksh M (2007) Design of multimode-circular microwave cavity for agri-food processing. In: Microwave conference, 2007. APMC 2007. Asia-Pacific IEEE. pp 1–4.

[30]. Sakai N, Hanzawa T. Heat Transfer Analysis in Food Heated by Far-Infrared Radiation. Developments in Food Engineering.Springer USA; 1994.pp 313–315.

[31]. Ratti C. Shrinkage during drying of foodstuffs. J Food Eng. 1994 Jan 1;23(1):91-105.

[32]. Afzal TM, Abe T, Hikida Y. Energy and quality aspects during combined FIR-convection drying of barley. J Food Eng. 1999 Dec 1;42(4):177-82.

[33]. Hebbar HU, Vishwanathan KH, Ramesh MN. Development of combined infrared and hot air dryer for vegetables.J Food Eng. 2004 Dec 1;65(4):557- 63.

[34]. Krebbers B, Matser AM, Hoogerwerf SW, Moezelaar R, Tomassen MM, van den Berg RW. Combined high-pressure and thermal treatments for processing of tomato puree: evaluation of microbial inactivation and quality parameters. Innov Food SciEmerg. 2003 Dec 1;4(4):377-85.

[35]. Castro SM, Loey AV, Saraiva JA, Smout C, Hendrickx M. Inactivation of pepper (Capsicum annuum) pectin methylesterase by combined high-pressure and temperature treatments. J Food Eng. 2006;75(1):50–58.

[36]. Ukuku DO, Geveke DJ. A combined treatment of UV-light and radio frequency electric field for the inactivation of Escherichia coli K-12 in apple juice.Int J Food Microbiol. 2010 Mar 31;138(1-2):50-5.

[37]. Liu Y, Tang J, Mao Z, Mah JH, Jiao S, Wang S. Quality and mold control of enriched white bread by combined radio frequency and hot air treatment. J Food Eng. 2011 Jun 1;104(4):492-8.

[38]. Amiali M, Ngadi MO, Smith JP, Raghavan GS. Synergistic effect of temperature and pulsed electric field on inactivation of Escherichia coli O157: H7 and Salmonella enteritidis in liquid egg yolk. J Food Eng. 2007 Mar 1;79(2):689-94.

[39]. Bazhal MI, Ngadi MO, Raghavan GS, Smith JP. Inactivation of Escherichia coli O157: H7 in liquid whole egg using combined pulsed electric field and thermal treatments. LWT Food Sci Technol. 2006 May 1;39(4):420-6.

[40]. Gin B, Farid M. The use of carbon electrodes in ohmic cooking of meat patties. Asia-Pacific J Chem Eng. 2007 Sep;2(5):474-9.

[41]. Erkmen O, Bozoglu TF. Food Microbiology, 2 Volume Set: Principles into Practice. John Wiley & Sons; 2016 Jun 13.

[42]. Barrow CJ, Nolan C, Jin Y. Stabilization of highly unsaturated fatty acids and delivery into foods. Lipid Technology. 2007 May;19(5):108-11.

[43]. Timilsena YP, Wang B, Adhikari R, Adhikari B. Preparation and characterization of chia seed protein isolate–chia seed gum complex coacervates. Food hydrocolloids. 2016 Jan 1;52:554-63.

[44]. Kaushik P, Dowling K, Barrow CJ, Adhikari B. Complex coacervation between flaxseed protein isolate and flaxseed gum. Food Research International. 2015 Jun 1;72:91-7.

[45]. Ducel V, Richard J, Popineau Y, Boury F. Adsorption kinetics and rheological interfacial properties of plant proteins at the oil− water interface. Biomacromolecules. 2004 Nov 8;5(6):2088-93.

[46]. Kaushik P, Dowling K, McKnight S, Barrow CJ, Adhikari B. Microencapsulation of flaxseed oil in flaxseed protein and flaxseed gum complex coacervates. Food research international. 2016 Aug 1;86:1-8.

[47]. Wang B, Li D, Wang LJ, Adhikari B, Shi J. Ability of flaxseed and soybean protein concentrates to stabilize oil-in-water emulsions. Journal of Food Engineering. 2010 Oct 1;100(3):417-26.

[48]. Wang B, Wang LJ, Li D, Adhikari B, Shi J. Effect of gum Arabic on stability of oil-in-water emulsion stabilized by flaxseed and soybean protein. Carbohydrate polymers. 2011 Aug 1;86(1):343-51.