Failure-Oriented-Accelerated-Testing And Its Role In Assuring Reliability Of Aerospace Electronics

E. Suhir*

Bell Laboratories, Murray Hill, NJ (ret), Portland State University, Portland, OR, and ERS Co., Los Altos, CA, 94024, USA.

*Corresponding Author

E. Suhir,

Bell Laboratories, Murray Hill, NJ (ret), Portland State University, Portland, OR, and ERS Co., Los Altos, CA, 94024, USA.

Tel: 650-969-1530

Email: suhire@aol.com

Received: November 11, 2022; Accepted: December 02, 2022; Published: December 05, 2022

Citation:E. Suhir. Failure-Oriented-Accelerated-Testing And Its Role In Assuring Reliability Of Aerospace Electronics. Int J Aeronautics Aerospace Res. 2022;09(2):274-290.

Copyright: E. Suhir© 2022. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Abstract

An highly focused and highly cost effective failure-oriented-accelerated-testing (FOAT) suggested about a decade ago as

an experimental basis of the novel probabilistic design for reliability (PDfR) concept is intended to be carried out at the

design stage of a new electronic packaging technology and when high operational reliability (like the one required, e.g., for

aerospace, military, or long-haul communication applications) is a must. On the other hand, burn-in-testing (BIT) that is

routinely conducted at the manufacturing stage of almost every IC product is also of a FOAT type: it is aimed at eliminating

the infant mortality portion (IMP) of the bathtub curve (BTC) by getting rid of the low reliability "freaks" prior to shipping

the “healthy” products, i.e., those that survived BIT, to the customer(s).When FOAT is conducted, a physically meaningful

constitutive equation, such as the multi-parametric Boltzmann-Arrhenius-Zhurkov (BAZ) model, should be employed to

predict, from the FOAT data, the probability of failure and the corresponding useful lifetime of the product in the field,

and, from the BIT data, as has been recently demonstrated, - the adequate level and duration of the applied stressors, as well

as the (low, of course) activation energies of the "freaks". Both types of FOAT are addressed in this review using analytical

("mathematical") predictive modeling, as well as FOAT carried out at the electronic product development stage. The general

concepts are illustrated by numerical examples. It is concluded that predictive modeling should always be conducted prior

to and during the actual testing and that analytical modeling should always complement computer simulations. Future work

should be focused on the experimental verification of the obtained findings and recommendations.

2.Introduction

3.Literature Review

4.Dimensional analysis and Similitude

5.Design procedure of gating and runners

6.Experimental Procedures

7. Conclusion

8. References

Keywords

Accelerated Life Testing (ALT); Bathtub Curve(BTC); Boltzmann-Arrhenius-Zhurkov (BAZ) Equation;

Burn-In-Testing (BIT); Failure-Oriented-Accelerated-Testing (FOAT); Highly Accelerated Life Testing (HALT); Infantmortality-

Portion (IMP); Probabilistic Design for Reliability (PDfR).

Background/Incentive

The bottleneck of an electronic, photonic, MEMS or MOEMS

(optical MEMS) system's reliability is, as is known, the mechanical

("physical") performance of its materials and structural elements

[1-5] and not its functional (electrical or optical) performance,

as long as it is not affected by the mechanical behavior of the

design. It is well known also that it is the packaging technology

that is the most critical undertaking, when making a viable, properly

protected and effectively-interconnected electrical or optical

device and package into a reliable product. Accelerated life testing

(ALT) [6-15] conducted at different stages of an IC package

design and manufacturing is the major means for achieving

that. Burn-in-testing (BIT) [16-23], the chronologically final ALT,

aimed at eliminating the infant mortality portion (IMP) of the

bathtub curve (BTC) prior to shipping to the customer(s) the

"healthy" products, i.e. those that survived BIT, is particularly important:

BIT is therefore an accepted practice for detecting and

eliminating possible early failures in the just fabricated products

and is conducted at the manufacturing stage of the product fabrication.

Original BITs used, as is known, continuously powering

the manufactured products by applying elevated temperature

to accelerate their aging, but today various stressors, other-thanelevated-

temperature, are employed in this capacity. BIT, as far

as "freaks" are concerned, is and always has been, of course, a

FOAT type of testing.

But there is also another, so far less well-known and not always

conducted today, FOAT [24-29] that has been recently suggested

in connection with the probabilistic design for reliability (PDfR)

concept [30-48]. Such a design stage FOAT, if decided upon,

should be conducted as a highly focused and highly cost effective undertaking. FOAT is the experimental foundation of the

PDfR concept and, unlike BIT, which is always a must, should

be considered, when developing a new technology or a new design,

and when there is an intent to better understand the physics

of failure and, for many demanding applications, such as, e.g.,

aerospace, military, or long-haul communications, to quantify the

lifetime and the corresponding, in effect, never-zero, probability

of failure of the product. Such a design-stage FOAT could be

viewed as a quantified and reliability-physics-oriented forty years

old highly-accelerated-life-testing (HALT) [49-52], and should be

particularly recommended for new technologies and new designs,

whose reliability is yet unclear and when neither a suitable HALT,

nor more or less established "best practices" exist.

When FOAT at the design stage and BIT at the manufacturing

stage are conducted, a suitable and physically meaningful constitutive

equation, such as, e.g., the multi-parametric Boltzmann-

Arrhenius-Zhurkov (BAZ) model [53-67], should be employed to

predict, from the test data, the probability of failure and the corresponding

useful lifetime of the product in the field.

Both types of FOAT and the use of the BAZ equation are addressed

in this review, and their roles and interaction with other

types of accelerated tests are indicated and discussed. Our analyses

use, as a rule, analytical ("mathematical") predictive modeling

[68-74]. In the author's opinion and experience, such modeling

should always complement computer simulations: these two major

modeling tools are based on different assumptions and use

different computation techniques, and if the calculated data obtained

using these tools are in agreement, then there is a good reason

to believe that the obtained data are accurate and trustworthy.

Failure-Oriented-Accelerated-Testing (FOAT)

Accelerated Testing

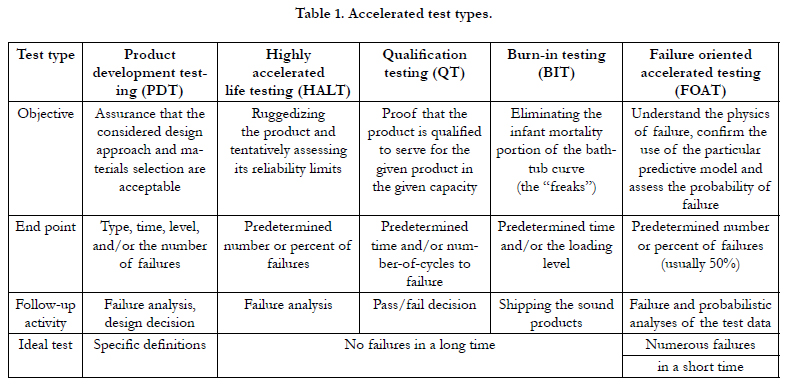

Accelerated testing [6-8] (Table 1) is a powerful means to understand,

prove, improve and assure an electronic or a photonic

product's reliability at all stages of its life, from conception to

failure ("death").

The product development tests (PDTs) are supposed to pinpoint

the weaknesses and limitations of the future design, materials,

and/or the manufacturing technology or process. These tests are

used also to evaluate new designs, new processes, the appropriate

correction actions, if necessary, and to compare different designs

from the standpoint of their expected reliability. This type

of testing is followed by the analyses of the observed failures,

or by other “independent” investigations, often based on predictive

modeling. Typical PDTs are destructive, i.e., are also of the

FOAT type. Temperature cycling (see, e.g.,[75-80]), twist-off [81],

shear-off (see, e.g., [82-84]) and dynamic (see, e.g., [85-87]) tests

are examples of PDTs aimed at the selection and evaluation of

the bonding material or a structural design. Predictive modeling

[88-97] is always conducted at this, initial, stage to design an adequate

test, to understand the physics of failures and to make

sure that the considered design approach and materials selection

are acceptable.

The objective of the qualification tests (QTs) in the today's practices

is to prove that the reliability of the product-under-test is

above a specified level. In the today's practices this level is usually

determined by the percentage of failures per lot and/or by the

number of failures per unit time (failure rate). Testing is time limited.

The analyst usually hopes to get as few failures as possible,

and his/hers pass/fail decision is based on a particular accepted

go/no-go criterion. Although the QTs are unable (and are not

supposed) to evaluate the failure rate, their results can be, nonetheless,

sometime used to suggest that the actual failure rate is at

least not higher than a certain value. This can be done, in a very

tentative way, on the basis of the observed percent defective in

the lot. QTs, in the best case scenario, are nondestructive, but

some level of failures is acceptable. If, however, the PDfR concept

is considered, the non-destructive QTs could be conducted

as a sort of quasi-FOAT that adequately replicates the initial nondestructive

stage of the previously carried out full-scale FOAT

whose data, including time-to-failure (TTF) and the mean-timeto-

failure (MTTF), are known and available by the time of the

QTs.

Understanding the underlying physics of failure is critical, and this

is the primary objective of the design stage FOAT. As has been

indicated, FOAT conducted at the design stage of the product development

is the experimental basis of the PDfR concept. While

QT is “testing to pass”, FOAT is “testing to fail” and is aimed at

confirming the underlying physics of failure anticipated by the use

of a particular predictive model (such as, e.g., multi-parametric

BAZ equation), establish its numerical characteristics (sensitivity

factors, activation energies, etc.), predict the probability of failure

and the corresponding time-to-failure (TTF) and the mean-timeto-

failure (MTTF) and to assess on this basis, using BAZ, the useful

life-time of the product and the corresponding probability of

failure in actual operation conditions. There are several more or

less well known constitutive FOAT models, other than BAZ, today:

power law (used when the physics of failure is unclear, e.g., in

proof-testing of optical fibers); Arrhenius’ equation (used when

there is a belief that elevated temperature is the major cause of

failure, which might be indeed the case when assessing the longterm

reliability of an electronic or a photonic material); Eyring’s

equation, in which the mechanical stress is considered directly (in

front of the exponent); Peck’s equation (the stressor is the relative

humidity); inverse power law (such as, e.g., Coffin-Manson’s and

related equations used in electronics packaging, when there is a

need to evaluate the low cycle fatigue life-time of solder joint interconnections,

if the inelastic deformations in the solder material

are unavoidable); Griffith’s theory based equations (used to assess

the fracture toughness of brittle materials and crack growth; it is

noteworthy that Griffith’s fracture mechanics cannot predict the

initiation of cracks, but is concerned with the likelihood and the

speed of propagation of fatigue and brittle cracks, including delaminations

– interfacial cracks); Miner’s rule (used to evaluate the

fatigue lifetime when the yield stress is not exceeded and the inelastic

strains are avoided); creep rate equations (used when creep

is important, often in combination with Coffin-Manson empirical

relationships); weakest link model (used to evaluate the TTF in

brittle materials with defects); stress-strength interference model,

that is widely employed in many areas of reliability engineering to

consider, on the probabilistic basis, the interaction of the strength

(capacity) of the material and structure of importance and the

applied stress (loading); extreme-value-distribution (EVD) based

model (used, when there is a reason to believe that it is only the

extreme values of the applied stressors contribute to the finite

lifetime of the material and device).

A highly focused and highly cost effective FOAT at the design

stage should be conducted for the most vulnerable materials and

structural elements of the design (reliability “bottle-necks”) in addition

to and, in many cases, even instead of the HALT, especially,

as has been indicated, for new products, for which no experience

is yet accumulated and no best practices are developed. FOAT

is a “transparent box” and could be viewed as an extension and

a modification of the forty years old HALT, which is a “black

box”. HALT is currently widely employed in different modifications,

with an intent to determine product’s reliability weaknesses;

assess, in a qualitative way, the reliability limits; ruggedize the

product by applying elevated stresses (not necessarily mechanical

and not necessarily limited to the anticipated field stresses) that

could cause field failures; and to provide, hopefully, large, but, actually,

unknown, safety margins over expected in-use conditions.

HALT tries to “kill many unknown birds with one big stone” and

is considered to be a “discovery” test. HALT is able to precipitate

and identify failures of different types and origins and even to

tentatively assess the reliability limits. HALT does that through a

“test-fail-fix” process, in which the applied stresses (“stimuli”) are

somewhat above the specified operating limits, but HALT does

not consider the physics of failure and is unable to quantify probability

on any basis, whether deterministic or probabilistic. HALT

can be used, however, for “rough tuning” of product’s reliability,

while FOAT could be employed, when “fine tuning” is necessary,

i.e., when there is a need to quantify, assure and even, if possible

and appropriate, specify the operational reliability of the device or

package. FOAT could be viewed therefore as a quantified and reliability

physics oriented HALT. If one sets out to understand the

physics of failure in an effort to create a highly reliable product,

conducting FOAT at its design stage is imperative. Both HALT

and the design stage FOAT should be geared, of course, to a particular

technology, product and application.

Probabilistic Design For Reliability (Pdfr) Concept

Reliability engineering is viewed in this concept as part of applied

probability and probabilistic risk management bodies of knowledge

and includes the product’s dependability, durability, maintainability,

reparability, availability, testability, etc., as probabilities

of occurrence of the reliability related events and characteristics

of interest. Each of these characteristics could be, of course, of a

greater or lesser importance, depending on the particular product,

its intended function, operation conditions and consequences of

its possible failure. The PDfR concept proceeds from the recognition

that nothing is perfect, and that the difference between a

highly reliable and an insufficiently robust product is “merely” in

the level of their never-zero probability of failure. This probability

cannot be high, of course, but does not have to be lower than

necessary either: it has to be adequate for a particular product and

application. An over-engineered and superfluously robust product

that “never fails” is, more likely than not, more costly than it could

and should be (see section 10 of this write-up).

Application of the probabilistic risk analysis concepts, approaches

and techniques puts the reliability assurance on the consistent

and “reliable” ground, and converts the art of creating reliable

packages into a physics-of-failure- and applied-probability-based

science. If such an approach is adopted, there will be a reason

to believe that an IC package that underwent HALT, passed the

established (desirably, improved) QT and survived BIT will not

fail in the field, owing to the predicted and very low probability

of possible failure (see section 3 of this review). By conducting

FOAT for the most vulnerable materials and structural elements

of the design and by providing a physically meaningful, quantifiable

and sustainable way to create a “generically healthy” product,

PDfR concept enables converting the art of designing reliable

packages into physics-of-failure and applied-probability based

science. After the probability of the operational failure predicted

from the FOAT data is evaluated, sensitivity analysis could be

carried out, if necessary, to determine what could possibly be

changed to establish the adequate level of this probability, if there

is a need for that. Such an analysis does not require any significant

additional effort, because it would be based on the already developed

methodologies and algorithms.

It is noteworthy that reliability evaluations should be conducted

for the product of importance on a permanent basis: the reliability

is “conceived” at the early stages of its design, implemented during

manufacturing, qualified and evaluated by electrical, optical, environmental and mechanical testing, checked (screened) during

production, and, if necessary and appropriate, maintained in the

field during the product’s operation. The prognostics and health

monitoring (PHM) methods and approaches would have much

better chances to be successful, if a “genetically healthy” package

is created. Thus, PDfR concept enables to improve dramatically

the state-of-the-art in the IC packaging reliability. The main features

of the PDfR concept could be summarized by the following

ten requirements (“commandments”): 1) The best product is

the best compromise between the needs (requirements) for its

reliability, cost effectiveness and time-to-market (completion); 2)

Reliability of an IC product cannot be low, but need not be higher

than necessary: it has to be adequate for a particular product and

application; 3) When adequate, predictable and assured reliability

is crucial, ability to quantify it is imperative, especially if high reliability

is required and if one intends to optimize reliability; 4) One

cannot design a product with quantified and assured reliability by

just conducting HALT; this type of accelerated testing might be

able to identify weak links in the product, but does not quantify

reliability; 5) Reliability evaluations and assurances cannot be delayed

until the product is made and shipped to the customer, i.e.,

cannot be left to the highly popular today PHM effort, important

as this activity might be; the PDfR effort is aimed, first of

all, at designing a "genetically healthy" product, thereby making

the PHM effort, if needed, more effective; 6) Design, fabrication,

qualification, PHM and other reliability related efforts should

consider and be geared to the particular device and its intended

application(s); 7) PDfR concept is an effective means for improving

the state-of-the-art in the field of IC packaging; 8) FOAT is

an important feature of PDfR; FOAT is aimed at understanding

the physics of failure, and at validation of a particular physically

meaningful predictive model; as has been indicated, FOAT

should be conducted in addition to, and sometimes even instead

of HALT; 9) Predictive modeling is another important constituent

of the PDfR, and, in combination with FOAT, is a powerful,

cost-effective and physically meaningful means to predict and

eliminate failures; 10) Application of consistent, comprehensive

and physically meaningful PDfR can lead to the most feasible QT

methodologies, practices, procedures and specifications.

Possible Classes Of Ic Products From The Standpoint Of

Their Reliability Level

Three classes of electronic or photonic products could be distinguished

and considered from the standpoint of the requirements

for their reliability, including the acceptable probability of failure:

1) The product has to be made as reliable as possible; failure is

a catastrophe and should not be permitted; cost although matters,

but is of a minor importance; examples are military, space or

other products, which, in general, are not manufactured in large

quantities; examples are electronics in a nuclear bomb, or in a

spacecraft, or in a long-haul communication system; 2) The product

is mass produced, has to be made as reliable as possible, but

only for a certain level of demand (stress, loading); failure is still

a catastrophe, but, unlike in the previous class, cost plays an important

role; 3) Reliability does not have to be high at all; failures

are permitted, but still should be understood and, to an extent

possible, restricted; examples are consumer, commercial, and agricultural

electronic devices. These classes differ by the acceptable

(specified) probability of failure and the corresponding lifetime.

It should be mentioned in this connection that the assessed and

established, based on the rules of classification societies, probability

that the hull of an ocean going vessel sailing for twenty

years in a row in North Atlantic, which is the most severe, from

the standpoint of wave and wind condition, region of the world

ocean, breaks in half is (see, e.g., [98, 99]). With this in mind, one

could require, e.g., that the probability of failure of an electronic

or a photonic product of the above three classes is, say, and ,

respectively. This is because of many favorable factors that affect

the probability of failure of a product, and completely different

consequences of failure.

Multi - Parametric Boltzmann - Arrhenius - Zhurkov (BAZ)

Equation

The equation

Eq 1

was suggested by (a Russian physicist) Zhurkov [58, 59] in the experimental

fracture mechanics as a generalization of the (Swedish

physical chemist) Arrhenius' equation [56, 57]

Eq 2

in the kinetic theory of chemical reactions to evaluate the mean

time τ to the commencement of the reaction. In Zhurkov's theory

τ is the mean time to failure (MTTF). The equation (2) states that

a certain level of the ratio 0 U

kT of the “activation energy” U0 to the

thermal energy kT, where k = 8.6173x10−5eV / K is Boltzmann’s constant

and T is the absolute temperature, is required for the chemical

reaction to get started. When used in fracture mechanics, an

effective activation energy 0

0

U kT ln U τ

γσ

τ

= = − triggers crack propagation,

i.e., characterizes the propensity of the material to the anticipated

failure mechanism. This mechanism is characterized in

fracture mechanics by a certain level of the strain energy release

rate. In the equations (1) and (2), τ0 is an experimentally obtained

time constant. The term "activation energy" was coined by Arrhenius.

The equation (2) is formally not different from the (Austrian

physicist) Boltzmann’s equation in the thermodynamic theory of

ideal gases [53-55]. The equation (1) was used by Zhurkov and his

associates, when conducting numerous mechanical tests, in which

the external tensile stresses σ were applied to notched specimens

at different elevated temperatures i.e. when the mechanical stress

and the elevated temperature contributed jointly to the finite

mechanical/physical lifetime of the materials under test. The τ

value is, in effect, the maximum value of the probability of nonfailure.

Indeed, using the exponential law of reliability P = exp(−λt)

and considering that the failure rate λ is reciprocal to the MTTF

λ 1 ,

τ

=

this law can be written as

Eq 3

Introducing (1) into this equation, the following double-exponential-

distribution for the probability of non-failure can be obtained:

Eq 4

The time derivative of this distribution is dP H(P) ,

dt t

= − where

H(P) = −Pln P is the entropy of the distribution. This derivative explains the physical rationale behind the distribution (4): the probability

of non-failure decreases with an increase in the time of

operation or testing and increases with an increase in the entropy

of the distribution. The entropy H(P) is zero at the initial moment

of time (t=0), when the probability of non-failure is P=1, and at

the remote moment of time (t →∞), when P = 0. Its maximum value

found from the condition dH(P) 0

dP

= is max

H 1 0.3679.

e

= = The probability

* P = P that corresponds to the maximum entropy Hmax determined

from the equation * * max

P ln P H 1

e

− = = is also *

P 1 0.3679.

e

= = Then the

formula (3) indicates that the maximum probability of non-failure

takes place at the moment of time t = τ 1

λ

= , which is the MTTF of

the physical process in question.

It has been recently suggested [56-87] that any stimulus (stressor)

of importance (voltage, current, thermal stress, elevated humidity,

vibrations, radiation, light output, etc.) or an appropriate combination

of these stimuli can be used to stress a microelectronic

or a photonic material, device, package or a system subjected to

FOAT. It was suggested also that the time constant 0

0

τ 1

λ

= in the

equations (1) or (2), can be replaced, when FOAT is considered

and depending on the application and the specifics of the particular

FOAT, by a suitable quantity that characterizes the degradation

process, such as, e.g., the product I * γ I , when the leakage current I

is viewed as an acceptable and measurable quantity during FOAT

(here I* is its critical value, and γI is the sensitivity factor), or the

product R * γ R , when the measured electrical resistance R is selected

as an acceptable degradation criterion and its critical value

R* is an indication of the occurred failure (here γR is the sensitivity

factor for the electrical resistance). Then, in the general case, such

a multi-parametric BAZ equation can be written as

Eq 5

Here C* is the critical value (an indication of the occurred failure)

of the selected, agreed upon, measurable and monitored criterion

C of the level of damage (such as, say, leakage current or electrical

resistance, or energy release rate), γc is its sensitivity factor, t is

time, σi is the i-th stressor, γi is its sensitivity factor, and kT is the

thermal energy.

Baz Example: Humidity-Voltage Bias

If, e.g., the elevated humidity H and the elevated voltage V are

selected as suitable FOAT stressors, and the leakage current I - as

the suitable measurable and monitored during the FOAT characteristic

of the accumulated damage, then the equation (5) can be

written as

Eq 6

The sensitivity factors and the activation energy can be determined

by conducting a three-step FOAT. At the first step testing

should be carried out for two different temperatures, T1 and T2,

keeping the levels of the relative humidity H and the elevated

voltage V the same in both tests. Recording the percentages P1

and P2 of non-failed samples for the testing times t1 and t2 , when

failures occur, i.e., when the monitored leakage current I reaches its critical value I* the following relationships could be obtained:

Eq 7

Since the numerator 0 H V U =U −γ H −γ V in these relationships

is kept the same, the following condition should be fulfilled

for the sensitivity factor γ1.

Eq 8

This condition could be viewed as an equation for the γ1 value and

has the following solution:

Eq 9

At the second step, FOAT at two relative humidity levels H1 and

H2 should be conducted for the same temperature and voltage.

This yields:

Eq 10

Similarly, by changing the voltages V1 and V2 at the third step of

FOAT one obtains:

Eq 11

Finally, the stress-free ("effective") activation energy can be found

from (6) as

Eq 12

for any consistent combination of humidity, voltage, temperature

and time.

Let, e.g., after 1 t = 35h of testing at the temperature of

0

1 T = 80 C = 353K, the voltage of V = 600 V and the relative humidity

of H = 0.85%, the allowable (critical) level I* = 3.5μA of

the leakage current was exceeded in of the tested samples, so that

the probability of non-failure is P1 = 0.9. After t2 = 70h, of testing

at the somewhat higher temperature of t2 = 120°C = 393 K, but

at the same voltage and the same humidity, of the tested devices

exceeded the above critical level, so that the probability of nonfailure

was only P2 = 0.4. Then the second formula in (8) yields:

Eq A

and the sensitivity factor for the leakage current in the situation in

question can be found from (9) as

Eq B

This concludes the first FOAT step. At the second step, tests at

two relative humidity levels H1 and H2 were conducted for the

same temperature and voltage. Let, e.g., after t1 = 40h of testing at

the relative humidity level of H1 = 0.5 at the voltage V = 600V

and temperature T = 60°C = 333K, 5% of the test specimens

failed (P1 = 0.95), and after t2 = 55h at the same temperature and

the relative humidity level of H2 = 0.85, 10% of the test specimens

failed (P2 = 0.90). Then

Eq C

With k = 8.6173x10−5eV / K, the sensitivity factor for the relative

humidity can be found from (10) as

Eq D

At the third step, FOAT at two different voltage levels

V 600V 1 = and 1000 , 2 V = V have been carried out, for the

same temperature-humidity bias,T = 850C = 358K and H =

0.85 and it has been determined that 10% of the tested specimens

failed after t1 = 40h of testing (P1 = 0.9), and of the specimens

failed after t2 = 80h of testing (P2 = 0.8). Then we obtain:

Eq E

The calculated activation energy is therefore

Eq F

No wonder that the stress-free activation energy is determined

primarily by the third term in this equation. In an approximate

analysis only this term that characterizes the materials could be

considered. On the other hand, the level of the applied stressors

is also important: in this example the stressors contributed about

6.4% to the total activation energy. As is known, the activation

energy is equal to the difference between the threshold energy

needed for the reaction and the average kinetic energy of all the

reacting molecules/particles, but, as evident from the carried out

example, this difference could be affected by the type and level of

the external loading as well. It is noteworthy also that although

the input data in this example are hypothetical (but, hopefully,

more or less realistic), the level of the obtained activation energy

is not very far away from what is reported in the literature. Activation

energies for some typical failure mechanisms in semiconductor

devices are: for semiconductor device failure mechanisms

the activation energy ranges from 0.3 to 0.6eV; for inter-metallic

diffusion it is between 0.9 and 1.1eV. for metal migration 1.8eV;

for charge injection 1.3eV; for ionic contamination 1.1eV; for Au-

Al inter-metallic growth 1.0eV; for surface charge accumulation

1.0eV; for humidity-induced corrosion 0.8-1.0eV; for electro-migration

of Si in Al 0.9eV; for Si junction defects 0.8eV; for charge

loss 0.6eV; for electro-migration in Al 0.5eV; for metallization

defects 0.5eV. Some manufacturers use Arrhenius law with an

activation energy of 0.7eV for whatever material and the actual

failure mechanism might be.

BAZ Example: Hall's Concept

Pete M. Hall [75] suggested in his, now classical, experimental

approach to the assessment of the reliability of solder joint interconnections

experiencing inelastic deformations that the interconnection

under test be placed between a ceramic chip carrier

(CCC)/package and a printed circuit board (PCB). During temperature

excursions the solder joints experience thermal strains

caused by the CTE mismatch of the chip carrier and the board.

The possible failure modes were electrical failures (“opens”). Hall

measured, using strain gages, the in-plane and bending deformations

of the CCC and the PCB and, based on these measurements,

calculated the forces and moments experiencing by the

solder joints. The most important finding in Hall’s investigation

is that “upon repeated temperature cycling, there is a repeatable

stress-strain hysteresis, which is attributed to plastic deformations

in the solder”. In Hall’s experiments the gages were placed on

both sides of the CCC (package). The strains in his experiments

were measured in the middle of the assembly and it was assumed

that they were “isotropic and uniform” in the plane. An important

simplification in Hall’s experiments was the consideration of a

“model with axial symmetry”, assuming "that the solder posts can

be treated as if they were in a circular array and thus all equivalent”.

This is, of course, not the case in actual soldered assemblies:

it is the peripheral joints that exhibit the highest deformations.

The strength and the novelty of the pioneering P. Hall’s work is

in the experimental part of his effort. The strains were measured

as functions of temperature using commercial metal foil strain

gages. Hall concludes that plots of the thermally induced force

vs. displacement “can be used to yield the plastic strain energy

dissipated per cycle in the solder” and that “this energy can be

used to quantify micro-structural damage and eventually to predict

lifetimes in thermal chamber cycling”. It is this recommendation

that is used in the analysis that follows. We apply, however,

more realistic assumptions for the phenomena of interest, when

using the BAZ model.

The probability of non-failure of a solder joint interconnection

experiencing inelastic strains during temperature cycling can be

sought in the form of the BAZ equation as follows:

Eq 13

Here 0U ,eV, is the activation energy and is the characteristic of

the solder material’s propensity to fracture, W,eV, is the damage

caused by a single temperature cycle and measured, in accordance

with Hall’s concept, by the hysteresis loop area of a single

temperature cycle for the strain of interest, T is the absolute temperature (say, the cycle’s mean temperature), n is the number of

cycles, k,eV / K is Boltzmann’s constant, t,s, is time, R,Ω, is

the measured (monitored) electrical resistance at the joint location,

and γ is the sensitivity factor for the electrical resistance R.

The equation (13) makes physical sense. Indeed, the probability

P of non-failure is zero at the initial moment of time t = 0 and/

or when the electrical resistance R of the joint material is zero.

This probability decreases, because of material aging and structural

degradation, with time, and not necessarily only because of

temperature cycling. It is lower for higher electrical resistance (a

resistance of, say, 450 Ω can be viewed as an indication of an irreversible

mechanical failure of the joint). Materials with higher

activation energy U0 have a lower probability of possible failure.

The increase in the number of cycles leads to lower effective activation

energy 0 U =U − nW , and so does the level of the energy W

of a single cycle. The MTTF τ is

Eq 14

Mechanical failure, associated with temperature cycling, occurs,

when the number n of cycles is 0 . f

n U

W

= When this condition

takes place, the temperature in the denominator in the parentheses

of the equation (13) becomes irrelevant, and this equation

results in the following formula for the probability of non-failure:

Eq 15 and 16

If, e.g., 20 devices have been temperature cycled and the high

electrical resistance 450 , f R = Ω considered as an indication

of failure was detected in 15 of them, then 0.25 f P = . If the

number of cycles during such a FOAT were, say, nf = 2000, and

each cycle lasted, say, 20min=1200s., then the predicted TTF is

2000 1200 24 105 27.7778 , f t = x = x s = days and the formulas

(15) and (16) yield:

Eq G

Note that the MTTF is naturally and appreciably shorter

than the TTF. Let, e.g., the area of the hysteresis loop was

W = 4.5x10−4 eV. the stress-free activation energy of the solder

material is 4

0 2000 4.5 10 0.9 . f U = n W = x x − = eV To assess the

number of cycles to failure in actual operation conditions one

could assume that the temperature range in these conditions is,

say, half the accelerated test range, and that the area W of the

hysteresis loop is proportional to the temperature range. Then

the number of cycles to failure is

If the duration of one cycle in actual operation conditions is, say, one

day, then the time to failure will be 7200 19.726 .

Baz Example: Optical Silica Fiber Intended For Outer Space

Applications

Considering a situation, when an optical silica fiber, intended for

space applications, is subjected to the combined action of low

temperatures T, tensile stress σ, ionizing radiation D and random

vibrations of the magnitude V, its time-dependent probability P

= P (t) of non-failure could be sought in the form:

Eq 17

Here t is time, T is temperature, kT is thermal energy,

Eq 18

is the effective activation energy, U0 is the stress-free activation

energy and the γ factors reflect the fiber sensitivities, as far as its

propensity to fracture is concerned, to the changes in the applied

stressors: γt - to the change in temperature, γσ - to the change in

the tensile stress, γD - to the change in the ionized radiation and

γv - to the change in the level of random vibrations. Note that as

long as the activation energies U and U0 and the thermal energy

kT are expressed in eV, the factor γσ is expressed in eVkg−1mm2 ,

if the applied tensile stress is in kg/mm2; the factor γD - in 1

Y eVG −

, if the absorbed dose of ionizing radiation is measured in Grays

(as is known, 1.0Gy or 1.0Gray is the SI unit of absorbed dose of

ionizing radiation equal to 1 joule of radiation energy absorbed

per one kg of matter); and the factor γv is in eVxHzx(m / s2 )−2 , if the level of the random vibrations is measured in (vibration acceleration squared per unit frequency). It is noteworthy

that if other more or less significant loadings act concurrently

with those considered in the formula (18), these loadings could be

also considered in this formula for the effective activation energy.

The distribution (17) contains five empirical parameters: the

stress-free activation energy U0 and four sensitivity factors γ: the

time factor γt, the tensile stress factor γσ, the radiation factor γD

and the random vibrations factor γv. These factors and the activation

energy U0 could be obtained from a four step FOAT. At the

first step it should be conducted for two temperatures, T1 and

T2, keeping all the stressors that determine the effective activation

energy the same, whatever their level is. After recording the

percentages P1 and P2 of the non-failed samples the following

relationships can be obtained:

Eq 19

Here t1 and t2 are the times, at which failures occurred. Since the

effective activation energies U values were kept the same in these

relationships, the condition

Eq 20

must be fulfilled. Viewing this condition as an equation for the

time sensitivity factor γt, we obtain:

Eq 21

where the notations

Eq 22

are used. It is advisable, of course, that more than two FOAT series

and more than two temperature levels are considered, so that

the sensitivity parameter γt is evaluated with a high enough degree

of accuracy. At the second step testing at two stress-temperature

levels σ1 and T1, σ2 and T2, should be conducted, while keeping,

within this step of FOAT, the levels of the radiation and the random

vibration s the same in both sets of tests. Then the following

equations could be obtained for the probabilities of non-failure:

Eq 23

The unchanged amount in these test is

Eq G

where the notations (22) are used. Hence, the sensitivity

factor γσ can be obtained from the equation

Eq H

Eq 24

The time-probability parameters n1 and n2 are, of course, different

at each step and should be based on the probabilities of nonfailure

and the corresponding times at the given step. Similarly, by

keeping at the third step of FOAT the levels of stresses and random

vibration spectrum s in both sets of tests the same, and conducting

the tests for two radiation-temperature levels, the following

formula for the radiation sensitivity factor γD can be obtained:

Eq 25

At the fourth step testing at two vibration-temperature levels

should be conducted, while keeping the levels of tensile stress

and radiation the same. Then, using the same considerations as

above, the following formula for the sensitivity factor γV can be

obtained:

Eq 26

The effective activation energy can be evaluated now from (19) as

Eq 27

and the stress-free activation energy can be found from (18):

Eq 28

The expected static fatigue lifetime (time-to-failure, remaining

useful life) can be determined from (17) for the given probability

P of non-failure as

Eq 29

This time is, of course, probability of non-failure dependent and

changes from infinity to zero, when this probability changes from

zero to one.

Let, e.g., the following input FOAT information was obtained

at the first step of testing: 1) After t1 = 10h of testing at the

temperature of T1 = -200°C = 73K under the tensile stress of

σ = 420kg / mm2 , 25% of the test specimens failed, so that the

probability of non-failure is P1 = 0.75 in these tests; 2) After t2 =

8.0h of testing at the temperature of T2 = -250°C = 23K under

the same tensile stress, 10% of the samples failed, so that the

probability of non-failure is P2 = 090. Then the second formula

in (20) and the formula (22) yield:

Eq I

As one could see from the further evaluations, this sensitivity

factor is particularly critical, because it affects the other sensitivity

factors. At the second step testing is conducted at the stress

levels of 2

1 σ = 420kg / mm and 2

2 σ = 400kg / mm at the

temperatures 0

1 T = −200 C = 73K and 0

2 T = −150 C =123K,

respectively, and it has been confirmed that, indeed, 25% of the

samples tested under the stress of 2

1 σ = 420kg / mm failed after

1 t =10.0h of testing, so that indeed P1 = 0.75. The percentage

of samples failed at the stress level of 2

2 σ = 400kg / mm was

10% after t2 = 5.0h of testing, so that P2 = 0.90. Then, as follows

from (11),

Eq J

At the third step radiation tests have been conducted, and it has

been established that 1) After t1 = 35h of testing at the temperature

of 0

1 T = −270 C = 3K and after the total ionizing dose

of 1 D =1.0Gy =1.0J / kg (one joule of radiation energy absorbed

per kilogram of matter) was obtained, 65% of the tested

specimens failed, so that the recorded probability of non-failure

was P1 = 0.35; and that 2) After t2 = 50h of testing at the temperature of 0

T2 = −250 C = 23K and at the radiation level of

2 D = 2.0Gy = 2.0J / kg , 80% of the tested samples failed, so that

the recorded probability of non-failure was P2 = 0.20. Then the

formula (25) yields:

Eq K

At the fourth step FOAT for random vibrations was conducted.

Testing was carried out in two sets. The tensile stress (force) and

the level of radiation were kept the same in both of them. The

first set of tests was run for t1 = 12h at the temperature of T1 =

-180° C = 93K under the vibration level of S1 = 2.0mm2 s-3 and

was observed that 80% of the specimens failed by that time, so

that P1 = 0.2. The second set of tests was run for t2 = 7h at the

temperature of 0

2 T = −250 C = 23K under the lower vibration

level of 2 3

2 S =1.0mm s− and it was observed that only 40% of

the tested specimens failed by that time, so that P2 = 0.6. Then the

predicted sensitivity factor γv for the random vibrations is

Eq L

The effective activation energy U can be determined from (14) for

either of the two FOAT steps as

Eq M

and is, of course, very low. The stress-free activation energy can

be then found from (15) as

Eq N

The TTF t (in hours) can be evaluated for different temperatures

and for different probabilities of non-failure using the formula

(28):

Eq O

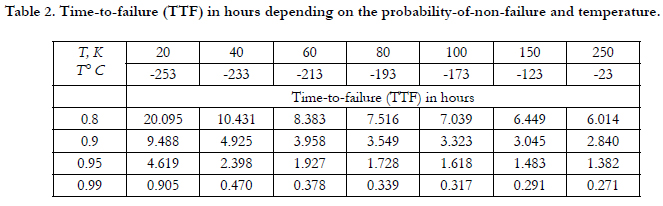

The calculated data are shown in Table 2. As evident from these

data, the TTF at ultra-low temperatures (note that BAZ equation

assumes that the life-time at zero absolute temperature might be

next-to-infinity) and at high values of the required (or expected) probabilities of non-failure are very sensitive to the changes in the

operation temperatures and in the corresponding probabilities of

non-failure.

PDfR Example: Adequate Heat Sink

As a simple PDfR example, examine a package whose probability

of non-failure during steady-state operation is determined by the

Arrhenius equation

Eq 30

This equation can be obtained from (4) by putting the external

stress σ equal to zero. Solving this equation for the temperature,

Let for the given type of failure (say, surface charge accumulation),

the ratio of the 0 U

k

of the activation energy to the Boltzmann’s

constant is U0 11600K,

k

= and the time constant predicted on the basis

of the FOAT is 8

0 τ = 5x10− h. Let the customer of the particular

package manufacturer requires that the probability of failure at

the end of the device service time of, say, t = 40,000h ≈ 4.6years

does not exceed Q =10−5 (see section 3), i.e., acceptable, if not

more than one out of hundred thousand devices fails by that time.

With P =1−10−5 = 0.9999 the above formula indicates that the

temperature of the steady-state operations of the heat-sink in the

package should not exceed T = 349.8K = 76.80C. Thus, the heat

sink should be designed accordingly, and the corresponding reliability

requirement should be specified for the vendor that provides

heat sinks for this manufacturer.

PDfR Example: Seal Glass Reliability In A Ceramic Package Design

The case of identical ceramic adherends was considered in connection

with choosing the adequate coefficient of thermal expansion

(CTE) for a solder (seal) glass in a ceramic package design

[99]. The package was manufactured at an elevated temperature of

about and hundreds of fabricated packages fell apart, when they

were cooled down to room temperature. It has been established

that it happened because the seal glass had a higher CTE than the

ceramic body of the package and because of that experienced

elevated tensile stresses at low temperature conditions. Of course,

the first step to improve the situation was to replace the existing

seal glass with the glass whose CTE is lower than that of the ceramics.

Two problems, however, arise: first, the compressive stress

experienced by the solder glass at low temperatures is applied to this material through its interfaces with the ceramics, and should

not be too high, otherwise structural failure might occur because

of the high interfacial shearing and peeling stresses, and second,

both the ceramics and the seal glass are brittle materials, and their

properties and, first of all, their CTEs are, in effect, random variables,

and therefore the problem of the interfacial strength of the

solder glass has to be formulated as the problem that the seal glass

at low temperature conditions is in compression, but this compression,

although guaranteed, should be rather moderate, i.e., the

probability that the acceptable interfacial thermal stress level is

exceeded should be sufficiently low. Accordingly, the problem of

the adequate strength of the seal glass interface was formulated as

the PDfR problem, and no single failure was observe in the packages

fabricated in accordance with the design recommendations

obtained on this basis.

Is It Possible That Your Product Is Superflously And Unnecessarily Robust?

While many packaging engineers feel that electronic industries

need new approaches to qualify and assure the devices’ operational

reliability, there exists also a perception that some electronic

products “never fail”. The very existence of such a perception

might be attributed to the superfluous and unnecessary robustness

of the particular product for the given application. Could

it be proven that a particular IC package is indeed “over-engineered”?

And if this is the case, could the superfluous reliability

be converted into appreciable cost-reduction of the product? To

answer these questions one has to find a consistent and trustworthy

way to quantify the product‘s robustness. Then it would

become possible not only to assure its adequate performance in

the field, but also to determine if a substantiated and well understood

reduction in its reliability level could be translated into an

appreciable cost savings.

The best product is, as is known, the best compromise between

reliability, cost effectiveness and time-to-market. The PDfR concept

makes it possible to optimize reliability, i.e., to establish the

best compromise between reliability, cost effectiveness and timeto-

market (completion) for a particular product and application.

The concept enables developing adequate QT methodologies,

procedures and specifications, with consideration of the attributes

of the actual operation conditions, time in operation, consequences

of failure, and, when needed and possible, even to specify

acceptable risks (the never-zero probability of failure). It is

natural to assume that higher reliability costs more money. In the

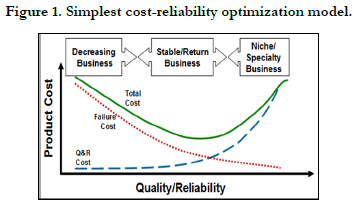

simplest, but nonetheless still physically meaningful, case (Fig.1)

[94], it is assumed that the reliability-level-dependent quality-andreliability

(Q&R) cost CR to improve reliability R (whatever its

meaningful criterion is) increases exponentially with an increase

in the difference between the reliability level R and its referenced

(specified) level R0 : CR = CR(0)e-r(R-R0). Here CR (0) = CR|R=R0

is the cost to improve reliability at its R0 level, and r is the sensitivity

factor of the reliability improvement cost.

Similarly, the cost of repair could be sought as a decreasing exponent

(0) f (F F0 ) ,

F F C = C e− − where CF(0) is the cost of removing

failures at the R0 level, and f is the sensitivity factor of the

restoration cost. It could be easily checked that the total cost C

= CR+CF has its minimum min 1 1 R F

C C r C f

f r

= + = +

, when

the condition R F rC = fC is fulfilled. It is natural to assume that

the sensitivity factors are reciprocal to the mean-time-to-failure

(MTTF) and to the mean-time-to-repair (MTTR) respectively.

On the other hand, since the steady-state availability is defined as

then the following formula for the minimum total reliability cost

can be obtained:

Thus, if availability is high, the minimum cost of failure is, naturally,

the cost of keeping the reliability level CR high (so that no

failures are likely to occur, or could be fixed in no time).

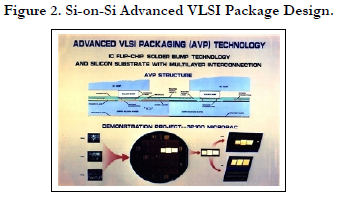

Application Of Foat: SI-ON-SI Bell Labs Vlsi Package Design

Si-on-Si Bell Labs VLSI package design was the first flip-chip

and the first multi-chip module design (Figs.2-4). All the major

steps in the PDfR approach were employed in this effort: analytical

modeling, confirmed by FEA, of the thermal stresses in the

solder joints modeled as short cylinders with elevated stand-off

heights (elevated height-to-diameter ratios), FOAT based on temperature

cycling, lifetime predictions based on the FOAT data.

Burn-In Testing (BIT): To Bit Or Not To Bit, That's The Question

BIT [16-23] is, as is known, an accepted practice for detecting and

eliminating early failures ("freaks") in newly fabricated electronic,

photonic, MEMS and MOEMS (optical MEMS) products prior

to shipping the “healthy” ones, i.e., those that survived BIT, to

the customer(s). This FOAT type of accelerated testing could be

based on temperature cycling, elevated (“baking”) temperatures,

voltage, current, humidity, random vibrations, light output, etc., or on a physically meaningful combination of these and other stressors.

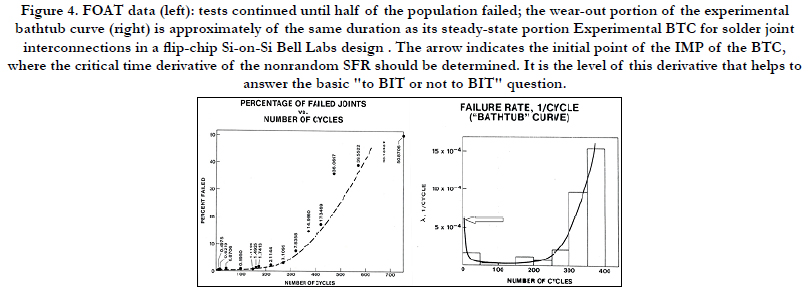

BIT is a costly undertaking. Early failures are avoided, and the

infant mortality portion (IMP) of the bathtub curve (BTC) (Fig.4)

is supposedly eliminated by conducting an adequate BIT, but this

result, if successful, is achieved at the expense of the reduced

yield. What is even worse, is that the elevated and durable BIT

stressors might not only eliminate undesirable “freaks,” but could

cause permanent and unknown damage to the main population

of the “healthy” products. The BIT effort should be therefore

well understood, thoroughly planned and carefully executed, so

that to convert, to an extent possible, this type of testing from a

"black box" of a Highly-Accelerated-Life-Testing (HALT) type to

a more or less "transparent" one, of the FOAT type.

First of all, it is even unclear whether BIT is always needed at

all, not to mention to what extent the current BIT practices are

effective and technically and economically adequate. HALT that

is currently employed as a suitable BIT vehicle of choice is, as is

known, a “black box” that more or less successfully tries “to kill

many birds with one stone”. This type of testing is unable to provide

any clear and trustworthy information on what BIT actually

does, on what is happening during and as a result of such testing

and how to effectively eliminate "freaks", if any, not to mention

what could possibly be done to minimize testing time, reduce the

BIT cost and duration and to avoid, or at least to minimize, damaging

the “healthy” products. Second of all, when HALT is employed

to do the BIT job, it is not even easy to determine whether

there exists a decreasing failure rate with time at the IMP of the

experimental BTC (Fig.4). There is, therefore, an obvious incentive

to find and develop ways to better understand and effectively

conduct BIT. Ultimately and hopefully, such an understanding

might enable even optimizing the BIT process, both from the reliability

physics and economics points of view.

Accordingly, in the analysis that follows some important BIT aspects

are addressed for a typical E&P product comprised of a

large number of mass-produced components. The reliability of

these components is usually unknown and their RFR could very

well vary in a very broad range, from zero to infinity. Three predictive

models are addressed in our analysis: 1) a model based on

the analysis of the IMP of the BTC (Fig.4); 2) a model based on

the analysis of the RFR of the components that the product of interest is comprised of and 3) a model based on the use of the

multi-parametric BAZ constitutive equation. The first model suggests

that the time derivative of the BTC’s initial failure rate (at

the very beginning of the BTC) can be viewed as a suitable criterion

to answer the "to BIT or not to BIT” question for this type

of failure-oriented accelerated testing (FOAT). The second model

suggests that the above derivative is, in effect, the variance of the

above RFR. The third model enables quantifying the BIT effort

and outcome by establishing the adequate duration and level of

the BIT’s stressor(s). All the three predictive models were developed

using analytical (“mathematical”) modeling.

Bit Model Based On The Bathtub Curve (BTC) Analysis

The steady-state mid-portion of the BTC (Fig.4), the “reliability

passport” of the manufacturing technology of importance, commences

at the left end of the BTC’s IMP. When time progresses,

the BTC ordinates reflect the results of the interaction of two

irreversible critical processes: the “favorable” statistical (SFR)

process that results in a decreasing failure rate with time, and the

“unfavorable” physics-of-failure-related (PFR) process associated

with the material's aging and degradation and resulting in an

increasing failure rate with time. The first process dominates at

the IMP of the BTC and is considered here. As is known, these

two processes more or less outweigh each other and result in the

steady-state portion of the BTC. The IMP of a typical BTC can

be approximated as [47]

Eq 31

Here λ0 is BTC’s steady-state minimum (failure rate at the end of

the IMP and at the beginning of its steady-state portion), λ1 is the

initial value of the IMP, t1 is the IMP duration, and the exponent

is expressed as

where β1 is the IMP “fullness”, defined as the

ratio of the area below the BTC to the area 1 0 1 (λ −λ )t

of the corresponding rectangular. The exponent n1 changes from

zero to one, when the “fullness” β1 changes from zero to 0.5. The

following expression for the time derivative λ'(t) of the failure rate

λ(t) could be obtained from (31):

Eq 32

At the initial moment of time (t=0) this derivative is

If this derivative is zero or next-to-zero, this means that the IMP

of the BTC is parallel to the horizontal, time, axis. If this is the

case, there is no IMP in the BTC at all, and because of that no

BIT is needed to eliminate the IMP of the BTC. Clearly, “not

to BIT” is the answer in this case to the basic “to BIT or not to

BIT” question. What is less obvious is that the same result takes

place for

This means that in such a case the IMP of the BTC does exist,

but almost clings to the vertical, failure rate, axis, and although

the BIT is needed in such a situation, a successful BIT could be

very short and could be conducted at a very low level of the applied

stressor(s). Physically this means that there are not too many

“freaks” in the manufactured population and that those that do

exist are characterized by very low activation energies and, because

of that, by low probabilities of non-failure. That is why the

corresponding required BIT process could be both low level and

short in time. The maximum possible value of the “fullness” β1 is,

obviously, β1 = 0.5. This corresponds to the case when the IMP

of the BTC is a straight line connecting the initial failure rate, λ1

and the BTC’s steady-state, λ0, values. The time derivative λ'(0) of

the failure rate at the initial moment of time can be obtained from

(32) for β1 = 0.5 as

and this seems to be the case,

when BIT is mostly needed. It will be shown in the next section

that this derivative can be determined as the RFR variance of the

mass-produced components that the product of interest under

BIT is comprised of.

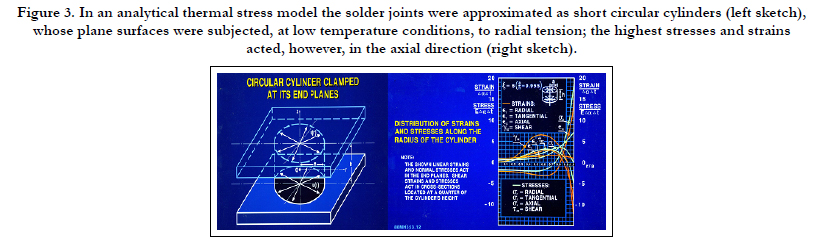

Figure 3. In an analytical thermal stress model the solder joints were approximated as short circular cylinders (left sketch), whose plane surfaces were subjected, at low temperature conditions, to radial tension; the highest stresses and strains acted, however, in the axial direction (right sketch).

Figure 4. FOAT data (left): tests continued until half of the population failed; the wear-out portion of the experimental bathtub curve (right) is approximately of the same duration as its steady-state portion Experimental BTC for solder joint interconnections in a flip-chip Si-on-Si Bell Labs design . The arrow indicates the initial point of the IMP of the BTC, where the critical time derivative of the nonrandom SFR should be determined. It is the level of this derivative that helps to answer the basic "to BIT or not to BIT" question.

Table 2. Time-to-failure (TTF) in hours depending on the probability-of-non-failure and temperature.

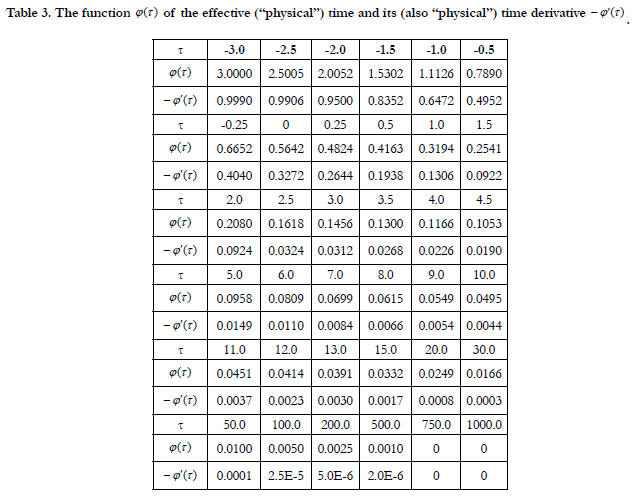

Table 3. The function ϕ (τ ) of the effective (“physical”) time and its (also “physical”) time derivative −ϕ′(τ ) .

Bit Model Based On The Statistical Failure Rate (SFR) Analysis

It is naturally assume that the RFR λ of the numerous mass-produced components that the product of interest is comprised of is normally distributed:

Eq 33

Here λ is the mean value of the RFR λ and D is its variance. Introducing (33) into the formula for the non-random statistical failure rate (SFR) in the BTC and using [100], the expression

Eq 34

for the non-random, “statistical”, SFR, λST(t) can be obtained. The term “statistical” is used here to distinguish, as has been indicated above, this, "favorable", failure rate that decreases with time from the "unfavorable" “physical” failure rate (PFR) that is associated with the material's aging and degradation and increases with time. The PFR is insignificant at the beginning of the IMP of the BTC and is not considered in our analysis. The function

Eq 35

depends on the dimensionless (“physical”, effective) time

Eq 36

and so do the auxiliary function

Eq 37

and the probability integral (Laplace function)

Eq 38

The ratio s in (36) can be interpreted as a sort of a measure of the level of uncertainty of the RFR in question: this value changes from infinity to zero, when the RFR variance D changes from zero (in the case of a deterministic, non-random, failure rate) to infinity (in the case of an "ideally random" failure rate. In the probability theory (see, e.g., [30]) such random process is known as “white noise”.

As evident from the formulas (36), the "physical", effective, time of the RFR process depends not only on the absolute, chronological, "actual", real time t, but also on the mean value λ − and the variance D of the RFR of the mass-produced components that the product of interest is comprised of. We would like to mention in this connection that it is well known, perhaps, from the times of the more than hundred years old Einstein’s relativity theory, that the “physical”, effective, time of an actual physical process or a phenomenon might be different from the chronological, "absolute", time, and is affected by the attributes and the behavior of the particular physical object, process or a system.

The rate of changing of the “physical” time τ with the change in the “chronological” time t is, as follows from the first formula in (36),

Eq 39

Thus, the “physical” time changes faster for larger standard deviations D of the RFR of the mass-produced components that the product of interest is built of.

Considering (39), the formula (34) yields:

Eq 40

As one could see from the first formula in (36), the “physical” time τ is zero, when the “chronological” time t is t D λ = and changes from -∞ to ∞, when the variance D of the RFR of the massproduced components that the product of interest is comprised of changes from zero, i.e., when this failure rate is not random, to infinity, when the RFR is "ideally random", i.e. of a “white noise” type. The calculated values of the function φ(t) expressed by (35) are shown in Table 3. This function changes from to zero when the “physical” time τ changes from to infinity, and the “chronological” time changes from zero to infinity. The tentative derivatives φ'(τ) are also calculated in this table.

The expansion (37) can be used to calculate the auxiliary function Φ(τ ) for large "physical" times τ, exceeding, say, 2.5 and has been indeed employed, when the Table 3 data were computed. The function Φ(τ ) changes from infinity to zero, when the “physical” time τ changes from -∞ to ∞. For the "physical" times τ below -2.5, the function Φ(τ ) is large, and the second term in (35) becomes small compared to the first term. In this case the function φ (τ ) is not different of the “physical” time τ itself, with an opposite sign though. As evident from Table 3, the derivative

can be put, at the initial moment of time, i.e., at the very beginning of the IMP of the BTC equal to -1.0, and therefore the initial time derivative of the SFR is

Eq 41

This fundamental and practically important result explains the physical meaning of the time derivative of the initial failure rate λ1 of the IMP of the BTC: it is the variance (with a sign “minus“, of course) of the RFR of the mass-produced components that the product undergoing BIT is comprised of.

Note that in the simplest case of a uniformly distributed RFR λ, when the probability density distribution function f(λ) is constant, the formula (34) yields:

Eq 42

In such a case the probability of non-failure becomes time independent, i.e. constant over the entire operation range:

This result does not make physical sense, of course, and therefore the normal distribution was accepted in this analysis. Future work should include analyses of the effect of various physically meaningful RFR probability distributions and their effect on the RFR variance. In the analysis carried out in the next section this variance is accepted as a suitable characteristic ("figure of merit") of the propensity of the product under the BIT to the BIT induced failure.

Bit Model Based On Using The Multi-Parametric Baz Equation

The BAZ equation [53-67], geared to the highly focused, highly cost effective, carefully designed, thoroughly conducted and adequately interpreted FOAT, is an important part of the PDfR concept [38-46] recently suggested for M&P products. This concept is intended to be applied at the stage of the development of a new technology for the product of importance. While in commercial E&P reliability engineering it is the cost effectiveness and time-tomarket that are of major importance, in many other areas of engineering, such as aerospace, military, medical, or long-haul communications, highly reliable operational performance of the M&P products is paramount and, because of that, has to be quantified to be improved and assured, and because of various inevitable intervening uncertainties in material properties, environmental conditions, states of stress and strain, etc., such a quantification should be preferably done on the probabilistic basis. Application of the PDfR concept enables predicting from the FOAT data, using BAZ equation, the, in effect, never-zero probability of the field failure of a material, device, package or a system. Then this probability could be made adequate and, if possible and appropriate, even specified for a particular product and application.

The probability of non-failure of a M&P product subjected to BIT, which is, of course, a destructive FOAT for the “freak” population, can be sought, using the BAZ model. Let us show how the appropriate level and duration of the BIT can be determined using the model

Eq 43

Here D is the variance of the RFR of the mass-produced components that the product of interest is comprised of, I is the measured/monitored signal (such as, e.g., leakage current, whose agreed-upon high enough value I* is considered as an indication of failure; or an elevated electrical resistance, particularly suitable when testing solder joint interconnections; or some other suitable physically meaningful and measurable quantity), t is time, σ is the appropriate “external” stressor, U0 is the stress-free activation energy, T is the absolute temperature, γσ is the stress sensitivity factor and γt is the time/variance sensitivity factor.

There are three unknowns in the expression (30): the product ; tρ =γ D the stress-sensitivity factor γσ and the activation energy U0. These unknowns could be determined from a two-step FOAT. At the first step testing should be carried out for two temperatures, T1 and T2, but for the same effective activation energy 0 U U σ = −γ σ . Then the relationships

Eq 44

for the probabilities of non-failure can be obtained. Here t1,2 are the corresponding times and I* is, say, the leakage current at the moment and as indication of failure. Since the numerator U = U0 - γσ in the relationships (44) is kept the same, the product ρ = γt - D can be found as

Eq 45 and 46

are used. The second step of testing should be conducted at two stress levels σ1 and σ2 (say, temperatures or voltages). If these stresses are thermal stresses that are determined for the temperatures T1 and T2, they could be evaluated using a suitable thermal stress model. Then

Eq 47

If, however, the external stress is not a thermal stress, then the temperatures at the second step tests should preferably be kept the same. Then the ρ value will not affect the factor γσ, which could be found as

Eq 48

where T is the testing temperature. Finally, the activation energy U0 can be determined as

Eq 49

The time to failure (TTF) is probability-of-failure dependent and can be determined as

TTF = MTTF(−ln P), where the MTTF is

Eq 50

Let, e.g., the following data were obtained at the first step of FOAT: 1) After t1 = 14h of testing at the temperature of T1 = 60°C = 333° K, 90% of the tested devices reached the critical level of the leakage current of I* = 3.5μA and, hence, failed, so that the recorded probability of non-failure is P1 = 0.1; the applied stress is elevated voltage σ1 = 380V; and 2) after t2 = 28h of testing at the temperature of T2 = 85° C = 358° K, 95% of the samples failed, so that the recorded probability of non-failure is P2 = 0.05. The applied external stress is still elevated voltage of the level σ1 = 380V. Then the formulas (33) yield:

Eq P

can be found from the formula (45) as follows:

Eq Q

At the FOAT's second step one can use, without conducting additional testing, the above information from the first step, its duration and outcome, and let the second step of testing has shown that after t2 = 36h of testing at the same temperature of T = 60°C = 333° K, 98% of the tested samples failed, so that the predicted probability of non-failure is P2 = 0.02. If the stress σ2 is the elevated voltage σ2 = 220V, then

Eq R

To make sure that there is no calculation error, the activation energies could be evaluated, for the calculated parameters n1 and n2 and the stresses σ1 and σ2, in two ways:

Eq S

No wonder that these values are considerably lower than the activation energies for the “healthy” products. As is known, many manufacturers consider as a sort of a “rule of thumb” that the level of 0.7eV can be used as an appropriate tentative number for the activation energy of “healthy” electronic products. In this connection it should be indicated that when the BIT process is monitored and the supposedly stress free activation energy U0 is being continuously calculated based on the number of the failed devices, the BIT process should be terminated, when the calculations, based on the FOAT data, indicate that the energy U0 starts to increase: this is an indication that the “freaks”, which are characterized by low activation energies, have been eliminated, and BIT is “invading” the domain of the “healthy” products. Note that the calculated data show also that the activation energy is slightly higher, by about 5-8%, for a higher level of stressing, i.e., is not completely loading independent. We are going to explain and account for this phenomenon as part of the future work.

The MTTF can be determined using the formula (37):

Eq T

The calculated probability-of-non-failure dependent time-tofailurte (lifetime) TTF =MTTFx (ln P) is 79.2h for P = 0.0075, is 74.5h for P = 0.0100 and is 48.5h for P = 0.050. Clearly, the probabilities of non-failure for a successful BIT, which is, actually, a carefully designed and effectively conducted FOAT, should be low enough. It is clear also that the BIT process should be terminated when the (continuously calculated during testing) probabilities of non-failure start rapidly increasing. How rapidly is “rapidly” should be specifide for a particular product, manufacturing technology and the accepted BIT process.

Conclusions

The following conclusions could be drawn from the above analysis.

• Predictive modeling should always precede the actual FOAT of

any type to make such testing physically meaningful, effective and

low cost.

• The bathtub-curve (BTC) based time-derivative of the statistical

failure rate (SFR) at the initial moment of time can be considered

as a suitable criterion ("figure-of-merit") of whether BIT for a

packaged IC device should or does not have to be conducted.

This derivative is, actually, the variance of the random failure rate

(RFR) of the mass-produced components that the manufacturer

of the product of interest received from various and numerous

vendors, whose commitments to reliability were unknown, and

therefore the RFR of these components might very well vary significantly,

from zero to infinity. This information enables answering

the fundamental “to BIT or not to BIT” question in electronics

manufacturing.

• Our analysis sheds light on the role and significance of several

important factors that affect the testing time and stress level: the

RFR of mass-produced components that the product of interest

is comprised of; the way to assess, from the highly focused and

highly cost effective failure-oriented-accelerated testing (FOAT),

the activation energy of the “freak” BIT population; the role of

the applied stressor(s); and, most importantly, - the probabilities

of the “freak” population failures depending on the duration and

level of the BIT effort. These factors should be considered when there is an intent to quantify and, eventually, to optimize the BIT’s

procedure.

• BAZ-based approach that was employed for that could be used

in many practically important undertakings and tasks, even beyond

the electronics engineering field, when quantification of a

materials reliability related problem is needed, and uncertain operation

conditions are inevitable and should be accounted for.

• The calculated data show also that the activation energy is slightly

higher, by about 5-8%, for a higher level of stressing, i.e., not

completely loading independent. We are going to explain and account

for this phenomenon as part of the future work as well.

• FOAT, being a transparent and reliability-physics-based “white/

transparent box”, can be viewed as an extension and a modification

of the forty-years-old and still highly (and justifiably) popular

highly-accelerated-life-testing (HALT). This “black box” has

many merits, but does not quantify reliability. In many cases, and

particularly, for new products, FOAT can and should be run even

as a substitution of HALT, especially for new products, for which

no experience is yet accumulated and best practices are not developed.

• Future work should include experimental verifications of the

suggested “to BIT or not to BIT” criterion, as well as its acceptable

values. It should include also investigation of the effects of

other possible distributions of the random SFR, such as, e.g., Rayleigh

or Weibull, and understanding that, in reality, there is no

such thing as loading independent activation energy: it looks like