Design and Analysis of 3/4 Power Series Rocket Nosecone

Gedlu Solomon*

Associate Researcher (M.Sc.), Ethiopia Space Science and Technology Institution, Addis Ababa, Ethiopia.

*Corresponding Author

Gedlu Solomon,

Associate Researcher (M.Sc.), Ethiopia Space Science and Technology Institution, Addis Ababa, Ethiopia.

Tel: +251973342296

Email: gedlusolomon076504@gmail.com

Received: July 15, 2020; Accepted: August 09, 2020; Published: August 11, 2020

Citation:Gedlu Solomon. Design and Analysis of 3/4 Power Series Rocket Nosecone. Int J Aeronautics Aerospace Res. 2020;7(3):230-234. doi: dx.doi.org/10.19070/2470-4415-2000028

Copyright: Gedlu Solomon© 2020. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Abstract

Drag is defined as the force that opposes forward motion through the atmosphere and is parallel to the direction of the free

stream velocity of the airflow, this paper included within different types of drag forces some of them are experienced in

rocket nosecone like form drag and skin friction drag also supersonic rocket experience additional drag is called wave drag,

finally reach on the conclusion that the length of nosecone 3.02976830 meter and total drag force experienced on nosecone

44,987.43173 kg m/sec2.

2.Introduction

3.Materials and Methods

4.Results and Discussions

5.Acknowledgement and Declarations

6.References

Keywords

Nosecone; Wave Drags; Skin Friction Drags; Form Drags; Induced Drags.

Introduction

In aerodynamics, drag is defined as the force that opposes forward

motion through the atmosphere and is parallel to the direction of

the free stream velocity of the airflow. Drag must be overcome by

thrust in order to achieves forward motion [1]. Form drags,Form

or pressure drag is cause by the air that is flowing over the aircraft

or airfoil. The separation of air creates turbulence and results in

pockets of low and high pressure that leaves a wake behind the

airplane or airfoil (thus the name pressure drags) this opposes forward

motion and is a component of the total drag. Since this drag

is due to the shape or form of the aircraft, it is also called form

drag. Streamlining the aircraft will reduce form drag. Skin friction

drag,skin friction drag is caused by the actual contact of the air

particles against the aircraft. This is the same as the friction between

any two objects or substances. Because skin friction drag is

an interaction between a solid (the airplane surface) and a gas (the

air), the magnitude of skin friction drag depends on the properties

of both the solid and the gas. For the solid airplane, skin friction

drag can be reduced and airspeed can be increased somewhat

by keeping an aircraft’s surface highly polished and clean.Wave

drag,wave drag is a drag, that retards the forward movement of an

airplane, in both supersonic and transonic flight, as a consequence

of the formation of shock waves.

Materials and Methods

Given the problem of the aerodynamic design of the nose cone

section of any vehicle or body meant to travel through a compressible

fluid medium (such as a rocket or aircraft, missile or bullet),

an important problem is the determination of the nose cone

geometrical shape for optimum performance [2]. The amount

of air resistance (drag) that opposes a rocket’s motion depends

mainly on the shape of the nose cone, the diameter of the rocket

and the speed of the rocket. The first point that meets the air is

the nose cone at the front end of the rocket. If the speed of a

rocket is less than the speed of sound, the best shape of a nose

cone is a rounded curve and at supersonic speeds (faster than the

speed of sound), the best shape is a narrower and sharper point.

Rockets with a larger diameter have more drag because there is

more air being pushed out of the way, making a rocket as narrow

as possible is the best way to reduce drag also the speed of a

rocket through the air similarly increases drag. As speed doubles,

drag increases four times as much [3].

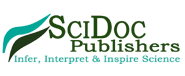

Wave-drag is induced by the nosecone, and as such, nosecones

are designed in order to bring down the drag force on the rocket

during flight. The magnitude of nosecone wave-drag is dictated by not only its shape but also by the rocket’s velocity and fineness

ratio, which is the ratio of a nosecone length to its largest diameter

[5]. There are many characteristic nosecone shapes which a

modern rocket nosecone may be modeled after namely the cone,

tangent ogive, ellipsoid, parabolic, power 0.5 and power 0.75.

As seen in figure 6.1 power 0.75 nosecone shape: at Mach number [0 to 1] nosecone drag coefficient insignificant, Mach number [1 to 1.5] nosecone drag coefficient relatively average, Mach number [1.5 to 6) best.let’s take as base diameter of D = 0.605953662 m.

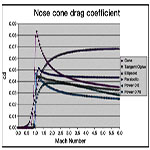

fineness ratio = L/D ------ (1)

L= 3.02976831 m

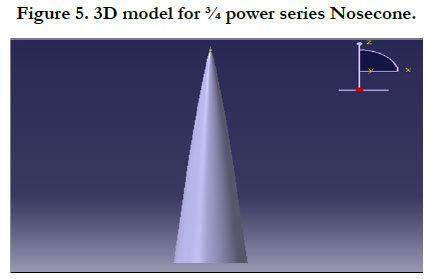

Configuration of ¾ Power series Nosecone

The Power Series includes the shape commonly referred to as a ‘parabolic’ nose cone, but the shape correctly known as a parabolic nose cone is a member of the Parabolic Series, and is something completely different. The Power Series shape is characterized by its (usually) blunt tip, and by the fact that its base is not tangent to the body tube. There is always a discontinuity at the nose cone/ body joint that looks distinctly non-aerodynamic. The shape can be modified at the base to smooth out this discontinuity. Both a flat-faced cylinder and a cone are shapes that are members of the Power Series. The Power series nose shape is generated by rotating a parabola about its axis. The base of the nose cone is parallel to the latus rectum of the parabola, and the factor n controls the ‘bluntness’ of the shape. As n decreases towards zero, the Power Series nose shape becomes increasingly blunt. At values of n above about 0.7, the tip becomes sharp [2].

y = R * (X/L)n ------ (2)

n = 0.75 for a 3/4 power

A = π* r2 ------ (3)

A= 0.288236174 m2 ----- (4)

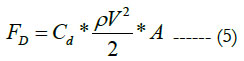

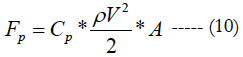

FD = 10,752.45173 kg m/sec2 (newton)

Where

FD = is the drag force

Cd = is the drag coefficient

A = is the reference area

ρ = is the density of the fluid

V = is the flow velocity relative to the object

Reynolds number, Reynolds number is a dimensionless value that

measures the ratio of inertial force to viscous force and describes

the degree of laminar or turbulent flow. Systems that operate at

the same Reynolds number will have the same flow characteristics

even if the fluid, speed and characteristics length vary.

Re = ρ *V * L / υ

Re = 289,748,110.2

Where

V = fluid velocity (m/s)

L = characteristics length, the chord width of an airfoil (m)

ρ =fluid density (kg/m3)

υ = fluid dynamic viscosity (kg/m.s)

Let consider the body is flat plane

but

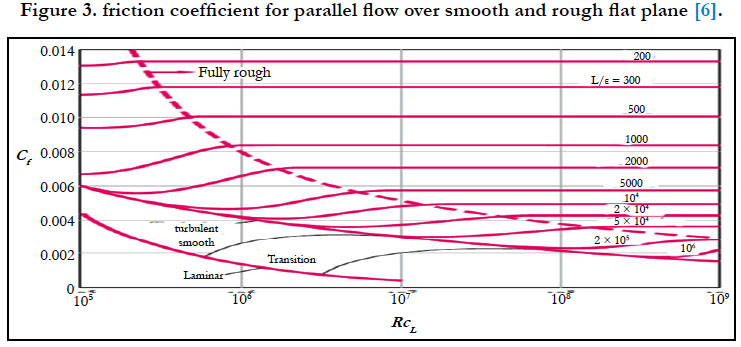

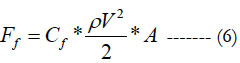

Cf = Skin friction coefficientand from figure 6.8, Cf = 0.002

A1 = L * C ---- (7)

A1 = 3.76140353 m2

A2 = π * r * hs ---- (8)

A2 = 2.944542314 m2

A = A1 + A2 ----- (9)

A = 6.705945844 m2

Ff = 6,291.74 kg m/sec2 (newton)

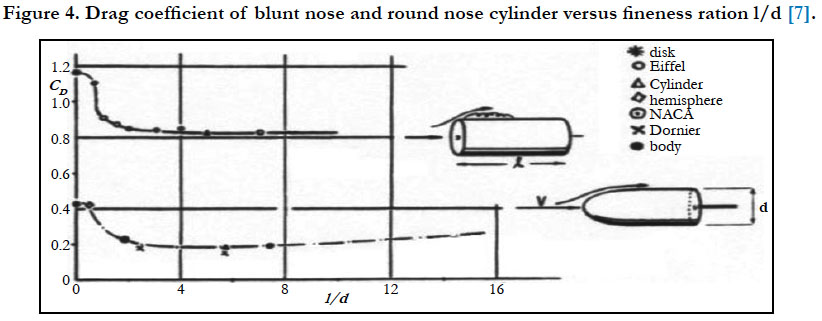

Let consider the body is long cylinder

A = πr2 ----- (11)

A = 0.297828147 m2

Fp = 27,943.24 kg m/ sec2 (newton)

A fiberglass is a form of fiber-reinforced plastic where glass fiber is the

reinforced plastic. This is the reason perhaps why fiberglass is also known

as glass reinforced plastic or glass fiber reinforced plastic. The glass fiber

is usually flattened into a sheet, randomly arranged or woven into a fabric.

According to the use of the fiberglass, the glass fibers can be made of

different types of glass. Fiberglass is lightweight, strong and less brittle.

The best part of fiberglass is its ability to get molded into various complex

shapes. This pretty much explains why fiberglass is widely used in

bathtubs, boats, aircraft, roofing, and other applications [8].

Depending on the raw materials used and their proportions to make

fiberglass, fiberglass can be classified into following major types:

• A-glass, is also called as alkali glass and is resistant to chemicals. Due

to the composition of A glass fiber, it is close to window glass. In some

parts of the world, it is used to make process equipment.

• C-glass, offers very good resistance to chemical impact and is also called

as chemical glass.

• E-glass,it is also called as electrical glass and is a very good insulator of

electricity.

• AE-glass,this is alkali resistant glass.

• S glass,it is also called as structural glass and is known for its mechanical

properties.

Fiberglass fabrics will not stretch or shrink. Nominal elongation break

is 3-4 percent. The average linear thermal expansion coefficient of “E”

glass is 5.4 by 10.6 cm/cm/°C [10].

pD = FD/AD = 37, 304.31049 pascal

pf = Ff/Af = 938.2330467 pascal

pp = Fp/Ap = 93,828.36855 pascal

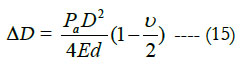

d = 0.004369576015 mm

take factor of safety 450 and d = 2 mm

ΔD = 0.047186816 mm

Results and Discussions

The following conclusion is drawn on nosecone length 3.02976830

meter: drag force due to shock wave 10,752.45173 kg m/sec2, drag

force due to skin friction 6,291.74 kg m/sec2, drag force due to

pressure (form drag) 27,943.24 kg m/sec2 and Nosecone Wall

Thickness 2 mm.

Acknowledgement and Declarations

They author of this paper appreciate Dr. Yeshurun Alemayehu,

Director of Space Engineering Research and Development,

Ethiopia Space Science and Technology institution, Addis Ababa,

Ethiopia for their valuable advice.

References

- Aeronotes.weebly.com [Internet]. Available from: https://aeronotes.weebly. com/types-of-drag.html

- Rimworld.com [Internet]. Nevada Aerospace Science Associates. Available from http://www.rimworld.com/nassarocketry/pdfs/050-NOSE%20 CONE%20DESIGN.pdf

- Sciencelearn.org [Internet]. University of Waikato; [cited 2011]. Available from https://www.sciencelearn.org.nz/resources/392-rocket-aerodynamics

- Apogeerockets.com [Internet]. Colorodo; [cited 2014 October 21]. Available from https://www.apogeerockets.com/education/downloads/Newsletter376. pdf

- Ideaexchange.uakron.edu [Interenet]. University of Akron; [cited 2018]. Available from https://ideaexchange.uakron.edu/cgi/viewcontent. cgi?article=1702&context=honors_research_projects.

- mheducation.com [Internet]. McGrawHill [cited 2014]. Available from https://www.mheducation.com/highered/product/fluid-mechanics-fundamentals- applications-cengel-cimbala/M9780073380322.html

- aerospaceweb.org [Internet]. Available from http://www.aerospaceweb.org/ question/aerodynamics/q0231.shtml

- phelpsgaskets.com [Internet]. Available from https://www.phelpsgaskets. com/blog/fiberglass--types-properties-and-applications-across-industries

- azom.com [Internet]. Available from https://www.azom.com/properties. aspx?ArticleID=769

- lewcospecialtyproducts.com [Internet]. Available from http://www.lewcospecialtyproducts. com/products/reinforcement-coating-laminating-fabrics/ properties-of-fiberglass-fabrics/